In precision manufacturing, broaching is one of the most effective methods for creating high-accuracy internal features such as keyways, splines, and serrations. However, the choice of material dramatically influences the broaching process. Stainless steel, aluminium, and brass each present unique cutting challenges due to differences in hardness, ductility, thermal conductivity, and chip formation behaviour. Selecting the right material early in the design stage is essential to ensure dimensional accuracy, surface finish, tool longevity, and overall process efficiency. Consulting with experienced broaching service providers can help engineers align material choice with process feasibility and performance requirements.

Introduction — Why Broaching Reacts Differently to Each Material

Broaching involves a progressive cutting action where a multi-tooth tool removes material in a single stroke. The material’s physical and mechanical properties dictate how the broach interacts with the workpiece:

- Hardness and tensile strength determine cutting forces, stress on the broach, and potential tool deflection.

- Ductility and elastic recovery affect part geometry and tolerances. For example, aluminum can spring back after cutting, leading to oversized keyways if not compensated.

- Thermal conductivity influences heat accumulation; stainless steel’s low thermal conductivity can cause localized heating, increasing the risk of work hardening and tool wear.

- Chip formation and flow vary across metals, influencing surface finish and tool life.

Failure to account for these factors can result in excessive tool wear, poor surface finish, dimensional inaccuracy, and even part rejection. Engineers specifying broached components must therefore understand material behavior to optimize tooling, cutting parameters, and post-broach finishing strategies.

Broaching Stainless Steel

Metallurgical Characteristics

Stainless steel is known for its corrosion resistance and mechanical strength, which comes from high chromium and nickel content. Its mechanical properties influence broaching in several ways:

- Work-hardening: As the broach engages the material, stainless steel hardens at the surface, increasing cutting resistance progressively.

- High shear strength: Stainless steel resists cutting, requiring greater broach forces and robust machine capabilities.

- Low thermal conductivity: Heat generated at the cutting interface tends to concentrate at the tool tip, accelerating wear and potentially affecting tolerances.

These characteristics make stainless steel one of the more demanding materials for internal broaching, especially for blind keyways, deep bores, or tight-tolerance applications.

Key Challenges

Broaching stainless steel introduces specific technical issues:

- Excessive cutting forces increase the likelihood of tool deflection, particularly in long or narrow keyways.

- Heat buildup can cause thermal expansion, leading to dimensional deviations and surface stress.

- Chip welding occurs when stainless steel adheres to the cutting teeth, creating poor surface finish and potential tool damage.

Solutions

Advanced techniques and tooling adjustments are critical to overcome stainless steel challenges:

- High-lubricity coolants reduce friction and heat accumulation.

- Coated broaches (e.g., TiAlN, AlCrN) resist abrasion and maintain sharp cutting edges.

- Optimized rake geometry allows smoother chip formation and prevents localized work hardening.

- Reduced feed per stroke limits cutting stress and minimizes the risk of surface tearing or end-wall distortion in blind keyways.

Applications

Stainless steel keyways and features are common in:

- Medical and surgical instruments requiring high corrosion resistance and precise tolerances

- Food-grade machinery, where sanitary and chemical-resistant surfaces are essential

- Aerospace mechanisms demanding high-strength, reliable torque transmission

Broaching Aluminum

Material Behavior

Aluminium is soft, ductile, and lightweight, making it easier to machine than stainless steel but presenting unique challenges:

- Chips tend to adhere to cutting edges, forming built-up edges.

- Material smearing can reduce surface finish quality, especially in blind keyways.

- Elastic recovery can result in oversized keyways if the broaching process is not carefully controlled.

Challenges

- Built-up edge formation reduces cutting efficiency and can damage the broach.

- Surface finish inconsistency due to smearing or chip adhesion.

- Dimensional variability caused by aluminium’s elastic spring-back after cutting.

Solutions

- Use diamond-polished cutting edges to minimize friction and chip adhesion.

- Employ sharp rake angles to improve chip evacuation.

- Implement high-speed broaching with excellent chip clearance to prevent smearing.

- Apply special lubricants suitable for non-ferrous materials to reduce heat and improve finish.

Common Applications

Aluminium broached components are widely used in:

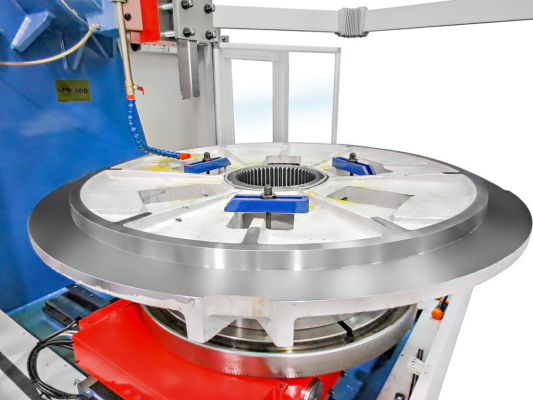

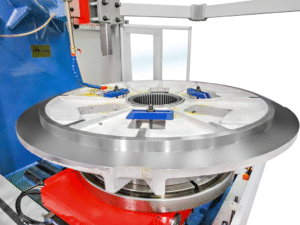

- Electric vehicle motor housings where lightweight materials reduce overall weight.

- Aerospace structures requiring tight tolerances with low-density components.

- Consumer electronics and precision devices with small internal keyways and splines.

Broaching Brass

Why Brass Is Easy to Broach

Brass is a free-machining alloy with excellent chip formation properties:

- Clean shear planes reduce cutting stress.

- Minimal heat generation prolongs tool life.

- Consistent material behaviour allows predictable broaching results.

Challenges

Despite its machinability, brass requires careful handling:

- Overcutting risk if feed rates are too aggressive.

- Brittle chips can lodge in blind pockets, potentially causing gouging.

Solutions

- Implement controlled feed rates to maintain dimensional accuracy.

- Use precision gauging after broaching to verify tolerances.

- Optimize hook and rake angles to prevent surface gouging or end-wall damage.

Applications

Brass broached components are commonly found in:

- Precision sensor housings

- Electrical connectors requiring clean internal keyways

- Small gearing components in compact mechanisms

Broaching Carbon Steels & Special Alloys

Carbon steels and specialty alloys introduce broader variability:

- Medium carbon steels are relatively machinable and suitable for high-volume keyway production.

- Hardened steels and nickel alloys require carbide tooling, reduced feeds, and precise stroke control to prevent tool breakage.

- Specialty alloys may also require heat management, coatings, or post-broach stress-relief processes.

The material selection dictates tooling requirements, cycle times, and tolerance achievable.

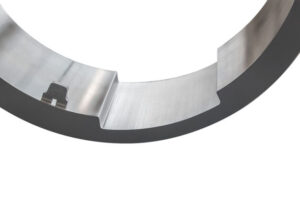

How Material Choice Affects Tolerances & Surface Finish

Surface Roughness Variability

- Stainless steel: rougher finish due to work-hardening

- Aluminium: smoother finish possible but prone to smearing

- Brass: consistently smooth if feed is controlled

Minimum Achievable Tolerances

| Material | Typical Tolerance | Notes |

| Stainless steel | ±0.02 mm | Requires coated tools and controlled feed |

| Aluminium | ±0.01 mm | Elastic recovery must be compensated |

| Brass | ±0.01–0.015 mm | Overcutting can occur if feeds are high |

Heat Influence on Dimensional Stability

- Low thermal conductivity in stainless steel leads to localized expansion.

- Aluminium and brass dissipate heat better but may exhibit spring-back.

- Controlling broach speed, stroke, and lubrication is essential to maintain tight tolerances.

Quality Control & Inspection for Different Materials

- Measure burr formation and remove as necessary.

- Check bore concentricity to ensure proper assembly.

- Evaluate micro-cracks in stainless steel, particularly in aerospace or medical components.

- Use CMMs or profile projectors for precise dimensional verification.

How Engineers Should Select Material for Broached Components

Engineers must balance:

- Mechanical properties (strength, hardness, fatigue resistance)

- Machinability to prevent excessive tooling cost

- Avoid alloys that excessively work-harden, smear, or spring-back

- Consult with broaching specialists early to align material choice with tooling, cutting parameters, and intended application

Conclusion

Different materials respond uniquely to broaching:

- Stainless steel requires careful heat and tool management for deep or blind keyways.

- Aluminium needs sharp cutting edges, high-speed broaching, and specialized lubrication.

- Brass is easy to machine but demands controlled feed rates to avoid overcutting.

Understanding material-specific behaviour is critical to maintaining tolerances, surface finish, and tool life. Engineers specifying components for broaching services benefit from early consultation to ensure designs are manufacturable, reliable, and cost-effective. For guidance on material selection or precision broaching, contact us to discuss tailored solutions.