In precision mechanical design, the internal spline profile is a critical factor in torque transmission, alignment, and component longevity. Involute spline broaching, parallel key spline broaching, and serration spline broaching each offer unique advantages depending on the application, material, and assembly requirements. Selecting the right spline type is essential to prevent premature wear, minimize backlash, and ensure repeatable performance. Internal broaching services play a vital role in producing high-precision profiles, ensuring tolerance compliance, and enabling high-volume production. Understanding the technical differences between these spline forms can help engineers optimize designs for automotive, aerospace, industrial machinery, and robotics applications.

Introduction – Why Spline Selection Matters in Mechanical Design

Splines are fundamental to torque-transfer designs, enabling secure coupling between shafts and mating components. Poor selection of spline geometry can lead to:

- Premature component wear or failure

- Increased assembly issues due to misalignment or backlash

- Higher manufacturing cost from rework or scrap

Each spline type dominates in specific scenarios: involute splines for smooth torque transfer in high-performance gear systems, parallel key splines for large industrial machinery, and serration splines for compact, high-torque applications. The use of internal broaching ensures repeatable accuracy, uniform tooth engagement, and surface finish quality critical factors in precision engineering.

Deep Overview of Broached Spline Types

Involute Splines Overview

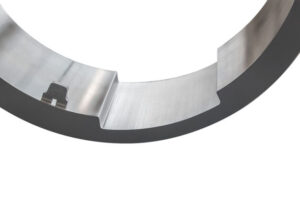

Involute splines feature a gear-like curved tooth profile. This geometry distributes stress evenly across the teeth, reduces peak loads, and provides self-centering capability. Involute profiles are standardized under ANSI and ISO forms, simplifying component interchangeability in global applications.

Parallel Key Splines Overview

Parallel key splines have straight-sided teeth, offering simplicity in load transfer and predictable contact behaviour. These are common in industrial machinery and commodity power transmission components where high volumes and robust performance are required.

Serration Splines Overview

Serration splines feature a high tooth count, enabling small diameters to carry significant torque. The compact multi-tooth engagement reduces backlash and allows for tight packaging constraints. These are particularly useful in steering columns, precision instruments, and compact tool drives.

Involute Splines — Design, Advantages & Broaching Requirements

Involute Geometry Explained

The involute curve is defined mathematically to ensure:

- Smooth root and flank engagement

- Accurate pressure angle function

- Predictable torque transfer under misalignment

This profile inherently accommodates minor shaft deflections and distributes loads efficiently.

Engineering Benefits

- Smooth torque transfer for high-performance machinery

- Self-centering for easy assembly

- Tolerance for moderate misalignment without excessive wear

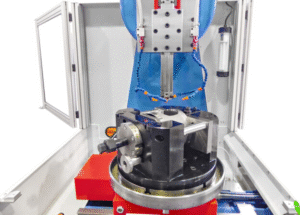

Broaching Involute Splines

Producing involute splines requires precise form grinding of broach teeth, careful tolerance stacking management, and advanced inspection methods such as CMM scans and involute measurement charts. Maintaining involute accuracy is critical for gear systems and high-speed rotating machinery.

Typical Industries

- Automotive transmissions

- Aerospace gear assemblies

- High-performance robotics

- Precision industrial machinery

Parallel Splines — Applications & Technical Characteristics

Geometry & Load Transfer

Parallel key splines transfer torque along vertical load paths, offering predictable stress distribution. Straight-sided splines are simpler to manufacture and ideal for applications with larger bore diameters.

Broaching Considerations

- Uniform chip load reduces tool stress

- Less complex tooling compared to involute splines

- High repeatability supports volume production

Best Applications

- Agricultural machinery

- Industrial power transmission

- High-volume commodity components

Serrations — High Tooth Density for Maximum Torque in Small Spaces

What Makes Serrations Unique

Serration splines provide multi-tooth contact, reducing backlash and enabling high torque transmission in compact diameters. This is advantageous where space constraints dictate component design.

Broaching Serrations

- Requires micro-profile tool precision

- Tool wear is accelerated due to high tooth density

- Sharp, coated cutting edges are essential for repeatable performance

Common Uses

- Steering columns and automotive linkages

- Precision instrumentation

- Small tool drives in industrial applications

Head-to-Head Profile Comparison

| Feature | Involute Spline | Parallel Key Spline | Serration Spline |

| Torque Transmission | Smooth, high | Moderate | High in small spaces |

| Misalignment Tolerance | High | Moderate | Low |

| Manufacturing Cost | Higher | Lower | Moderate |

| Tooling Complexity | High | Low | High |

| Volume Suitability | Medium | High | Low-Medium |

| Customizability | Moderate | Limited | High |

Strength & Torque Transmission

Involute splines handle misalignment and high speeds efficiently, while serration splines maximize torque in small diameters. Parallel key splines excel in large, robust industrial applications.

Misalignment Handling

Involute profiles naturally accommodate minor misalignment. Parallel splines require precise mating, and serrations have minimal tolerance for angular deviation.

Manufacturing Cost & Tooling Complexity

Through careful tool design, internal broaching services reduce cost and maintain precision for complex profiles. Involute and serration profiles demand higher tooling expertise compared to parallel splines.

Volume Suitability & Customizability

Parallel key splines are ideal for high-volume production, while involute and serration splines suit precision-critical applications with moderate volumes. Serrations are highly customizable for unique torque requirements.

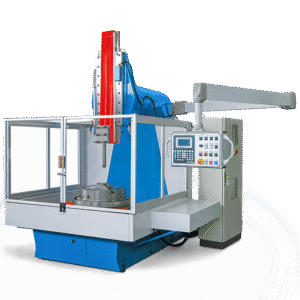

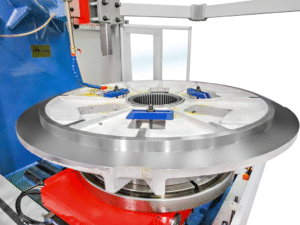

Internal Spline Broaching Capabilities Required

- Machine tonnage for high cutting forces

- Stroke length compatible with bore depth

- Tooling precision for tight tolerances

- Awareness of heat treatment effects on material hardness

- Post-broach finishing such as deburring and lapping for assembly readiness

Factors Engineers Must Consider When Selecting Spline Type

- Application torque requirements

- Rotational speed and acceleration

- Misalignment tolerance

- Bore diameter and mating shaft geometry

- Environmental conditions such as heat, corrosion, or vibration

How Specialized Broaching Services Add Value

Specialized internal broaching services provide:

- Custom spline design for application-specific performance

- Prototype-to-production scalability

- High-volume accuracy control

- Detailed inspection reporting for quality assurance

These services are essential for ensuring consistent performance across complex profiles and high-value components.

Conclusion

Selecting the right spline profile involute, parallel, or serration requires careful consideration of torque, misalignment, volume, and assembly constraints. Involute splines excel in smooth torque transfer and high-speed applications, parallel key splines support large, robust industrial machinery, and serrations provide high torque in compact spaces. Partnering with experienced internal broaching services ensures precise profile production, tooling optimization, and high-quality inspection, ultimately leading to reliable and repeatable mechanical performance. For consultation on your component design or broaching requirements, contact us to discuss tailored solutions.