Slotting Machine Tooling and Accessories

Discover high-precision broaching tools for keyways and premium slotting machine accessories engineered for durability, accuracy, and flexibility across both CNC and conventional machines.

Our solutions are trusted for demanding industrial applications where consistency, performance, and tool life are critical.

ABOUT US

With decades of manufacturing and engineering expertise, C.A.M.S. specialises in producing premium slotting machine tooling and accessories for precision broaching and slotting applications. Our commitment to engineering excellence, customisation, and reliability has made us a preferred supplier to manufacturers in the aerospace, automotive, defence, medical, and general engineering industries.

Tooling and Accessories Solutions

From heavy-duty broaching tools for keyways to advanced slotting machine accessories, we supply complete tooling solutions for both CNC and conventional operations. Our product range includes:

- Broaching tool sets

- Custom broaching tools

- Replacement tools for slotting machines

- Precision broach tooling for CNC machines

Each tool is manufactured to enhance machining accuracy, reduce vibration, and maximise production efficiency.

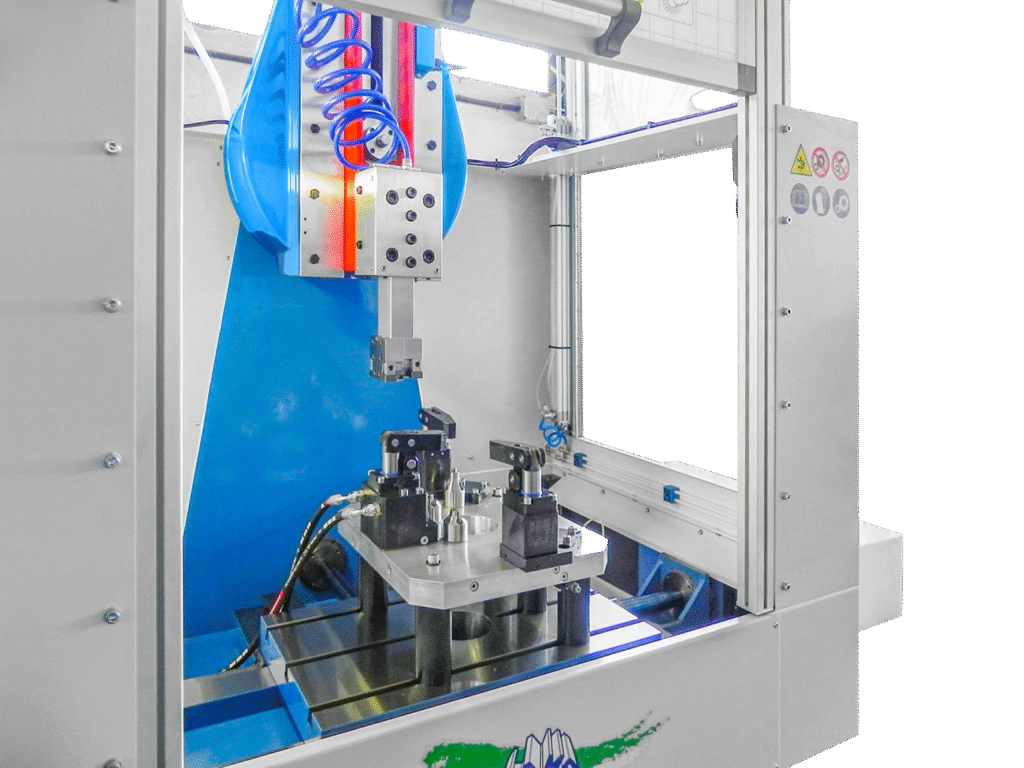

Machine Accessories

PRODUCT CATEGORIES

Equip your slotting machines with reliable, high-precision tools and accessories built for consistent performance and extended service life.

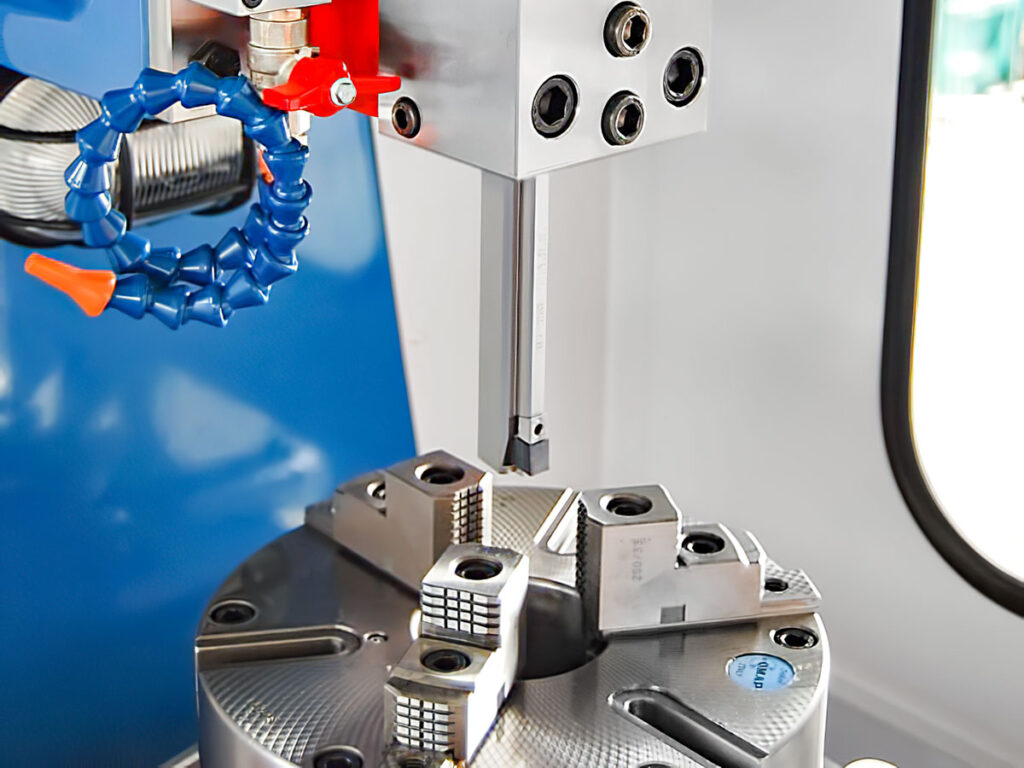

Keyway Broaching Tools

Designed for precise and repeatable internal and external keyway creation, our broaching tools for keyways offer tight tolerances, smooth surface finishes, and excellent dimensional consistency across various materials.

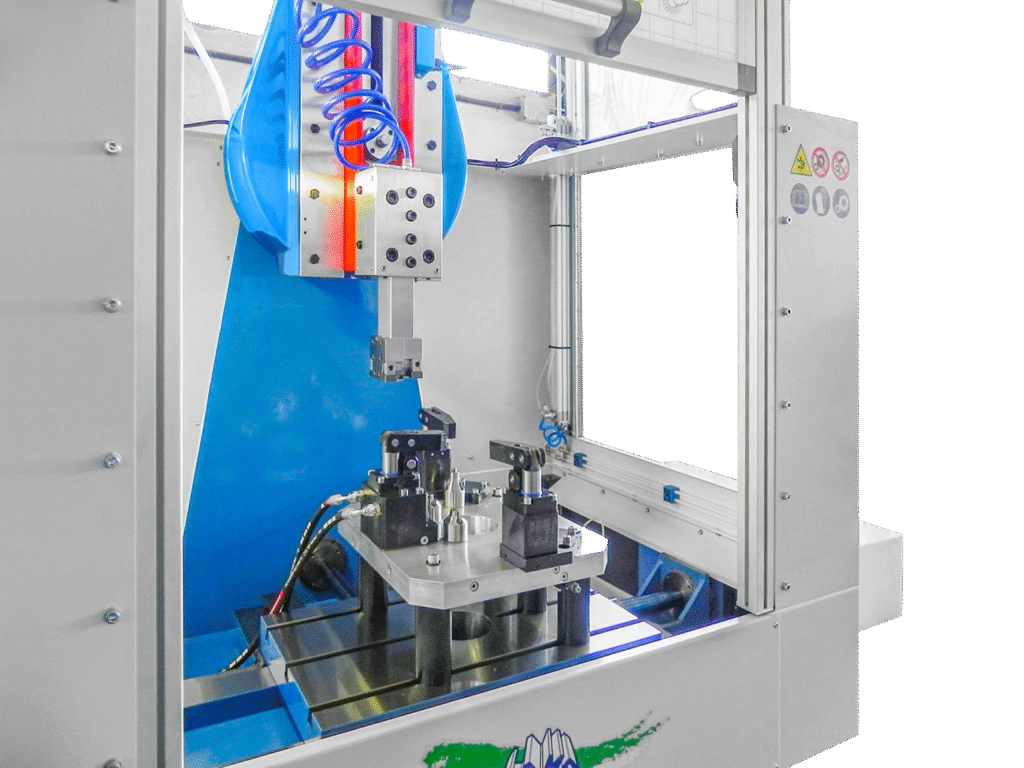

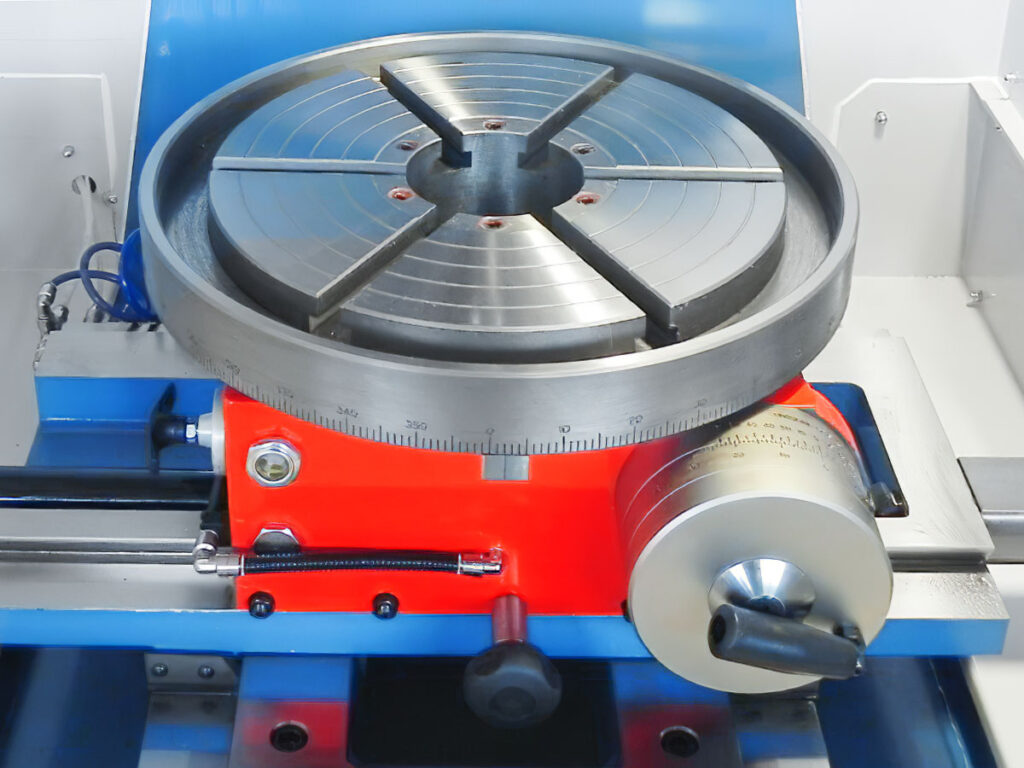

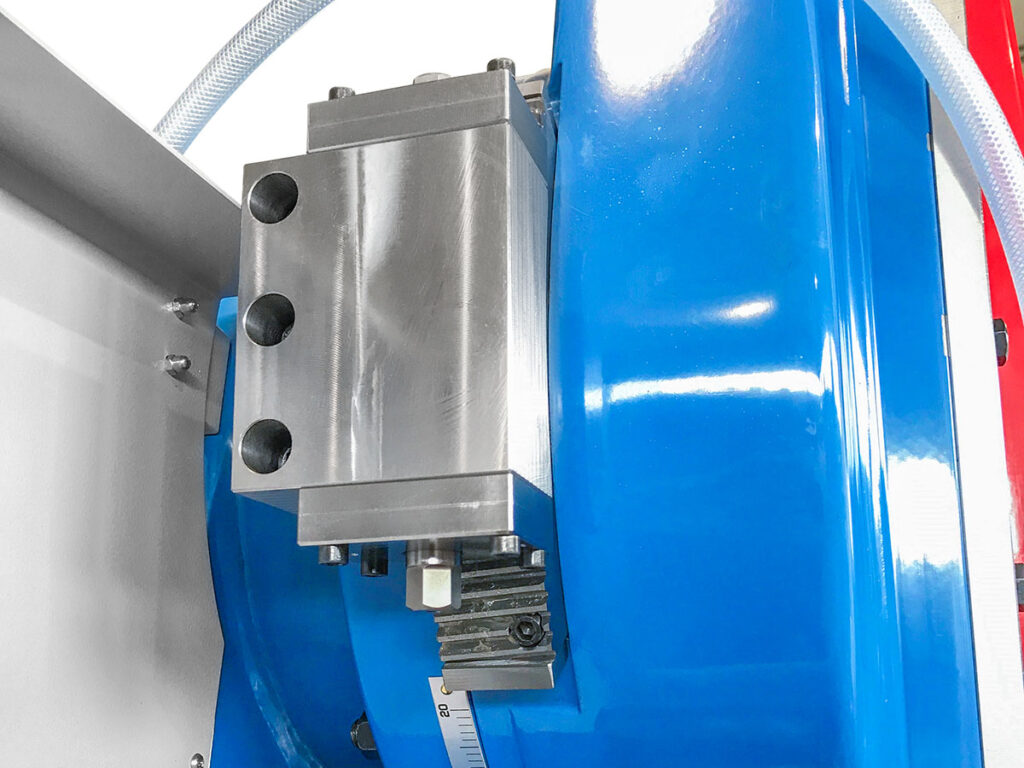

Slotting Machine Accessories

From workholding fixtures to clamping systems and alignment attachments, our slotting machine accessories improve machining stability, minimise setup time, and enhance overall productivity.

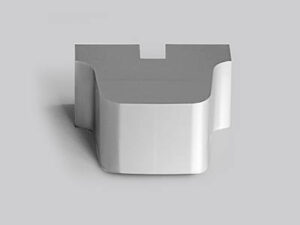

Custom Broaching Tools

Our custom broaching tools are designed to your exact specifications to accommodate special profiles, unconventional geometries, non-standard materials, and complex part requirements — all with high accuracy and repeatability

Replacement Tools for Slotting Machines

We offer a full range of replacement tools for slotting machines to minimise downtime and maintain production continuity without compromising accuracy or surface finish.

Broaching Tool Sets

Each broaching tool set includes essential profiles, sizes, and cutting configurations for versatile use in both CNC and manual machining operations.

Broach Tooling for CNC Machines

Our broach tooling for CNC machines is precision engineered for automated environments requiring speed, repeatability, and micron-level accuracy in high-volume production.

WHY CHOOSE US

Trusted by industry leaders worldwide, we deliver tooling and accessories that perform under pressure and stand the test of time.

- Precision Engineering : Every broaching tool set and slotting machine accessory is manufactured to exacting standards to deliver outstanding accuracy, consistency, and surface quality.

- Advanced Customisation Capabilities : We specialise in developing custom broaching tools for non-standard profiles, exotic materials, and specialised applications across multiple industries.

- Fast Fulfilment & Reduced Downtime : Our ready inventory of replacement tools for slotting machines ensures fast turnaround times and minimal production interruptions.

- Expert Technical Support: Our team assists you in selecting the most suitable broach tooling for CNC machines or conventional setups for seamless integration and optimal performance.

APPLICATIONS OF OUR TOOLING

Our slotting machine tooling and accessories are widely used in:

- High-Volume Manufacturing : Our broach tooling for CNC machines supports efficient, high-speed production cycles while maintaining tight tolerances and exceptional consistency.

- Aerospace & Defence Machining : We supply broaching tools for keyways and slotting machine accessories that meet stringent aerospace and defence industry standards for precision and reliability.

- Prototyping & Product Development : With custom broaching tools, engineers can efficiently test new designs, create prototypes, and accelerate R&D processes.

BENEFITS OF OUR TOOLING SOLUTIONS

Every product is engineered for quality, durability, and function, delivering measurable improvements to your machining process.

Superior Accuracy & Finish

Our broaching tools for keyways are manufactured to exact tolerances, ensuring consistent results across a wide range of materials.

Universal Compatibility

Designed for both C.A.M.S. machines and other industry-standard systems, our slotting machine accessories are compatible with CNC and manual setups alike.

Long Tool Life & Cost Efficiency

From custom broaching tools to replacement tools for slotting machines, our products are built for extended service life, reducing tooling changes and lowering overall operating costs.

UPGRADE YOUR SLOTTING SYSTEM

Upgrade your production capabilities with high-performance broaching tools for keyways and advanced slotting machine accessories designed to improve output, accuracy, and efficiency.

Frequently Asked Questions

What types of broaching tools for keyways do you offer?

We offer a comprehensive range of broaching tools for keyways in standard and custom sizes, suitable for internal and external keyway machining across multiple materials.

Are your slotting machine accessories compatible with all machines?

Yes, our slotting machine accessories are designed for most standard CNC and conventional slotting machines, with custom modifications available if required.

Can I request custom broaching tools for unique profiles or materials?

Absolutely. We design and manufacture custom broaching tools tailored to special geometries, uncommon alloys, and specific performance requirements.

Do you provide broach tooling for CNC machines?

Yes, we supply high-precision broach tooling for CNC machines optimised for automated, high-speed, and high-accuracy applications.

How do I know when to replace tools for slotting machines?

Common indicators include reduced accuracy, inconsistent finishes, excessive vibration, or visible wear. Timely replacement ensures consistent output and protects your machine.

What does a typical broaching tool set include?

A standard broaching tool set typically includes multiple cutters, profiles, sizes, and holders designed for flexible application across various jobs.

Do you provide technical support for tool selection?

Yes. Our technical team is available to assist with tooling selection, application advice, and custom tooling consultations.