Precision machining is at the heart of modern manufacturing, especially in sectors like aerospace, automotive, and industrial machinery. Components such as gears, shafts, and couplings often require internal grooves, splines, and keyways, which must be machined to exacting tolerances. Slotting machines, unlike traditional milling or broaching operations, offer a combination of precision, flexibility, and repeatability that is critical for high-quality components.

Among slotting machine manufacturers, C.A.M.S. stands out for its engineering excellence and proven performance. At Broaching Technologies, we supply and support C.A.M.S. machines, ensuring manufacturers in North America can access top-tier machinery with expert guidance.

By choosing a C.A.M.S. slotting machine, manufacturers benefit from machines designed for precision, adaptability, and longevity, all supported by local technical expertise and service.

A Brief History of C.A.M.S. and Its Engineering Legacy

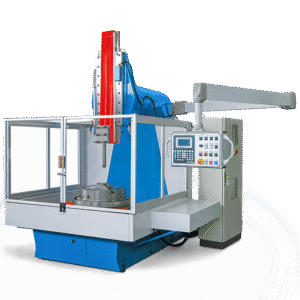

Founded in Italy, C.A.M.S. has decades of experience in manufacturing slotting machines for precision applications. The company’s focus has been on delivering machines that combine:

- Robust mechanical stability to minimize vibration and deflection during cutting operations

- High-precision capabilities for tight tolerance machining

- Versatility in handling a wide range of part geometries and materials

C.A.M.S. machines are widely recognized for their ability to maintain consistent accuracy across multiple parts and extended production runs, which is particularly valuable in industries with demanding component requirements, such as aerospace and automotive.

Key Technical Advantages of the C.A.M.S. Line

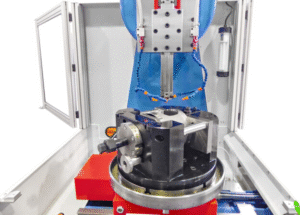

C.A.M.S. slotting machines provide features that make them exceptionally suited for modern manufacturing operations. These features address both precision and efficiency, ensuring high-quality output.

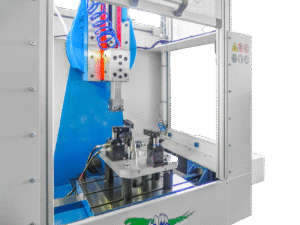

Precision Machining and Operational Flexibility

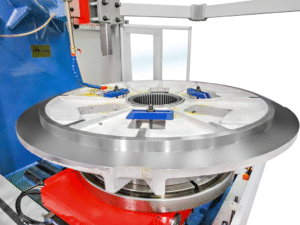

C.A.M.S. slotting machines are engineered to deliver repeatable accuracy. With rigid frames, electronically controlled feed mechanisms, and NC axes, these machines are capable of performing:

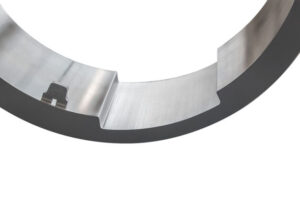

- High-precision groove cutting, ensuring minimal deviation in width and depth

- Spline cutting, including involute, parallel, and serration profiles

- Complex keyway operations, including blind and through keyways

This precision is essential for ensuring proper fit, torque transmission, and component longevity. Additionally, operational flexibility allows engineers to switch between different part profiles, materials, and production volumes with minimal downtime.

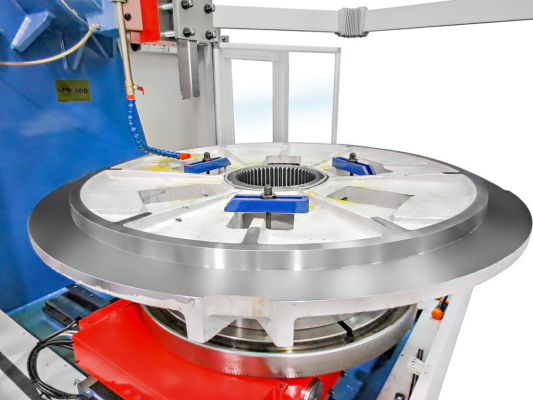

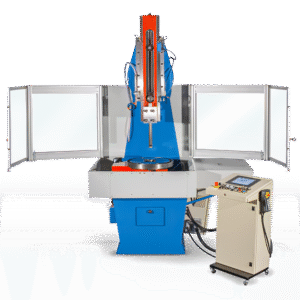

Machine Models and NC Axis Options

C.A.M.S. offers a range of models tailored to specific manufacturing needs:

- Model 200: Suitable for small parts and short-run production

- Model 400–600: Mid-sized parts such as shafts, gears, and couplings

- Model 850: Designed for large components and heavy-duty production

Each model can be equipped with 1–4 NC-controlled axes, providing:

- Precise angular indexing for spline teeth and grooves

- Multi-step operations without manual repositioning

- Repeatable accuracy across all parts in a batch

These capabilities enable manufacturers to handle complex components efficiently, reducing setup time and increasing throughput.

Applications Where C.A.M.S. Machines Excel

C.A.M.S. slotting machines are versatile, making them suitable for numerous high-precision applications:

| Application | Details |

| Groove Machining | Internal and external keyways, channels, and slots for shafts, gears, and couplings |

| Spline Machining | Involute, parallel, and serration splines with consistent spacing and accuracy |

| Heavy Production Runs | High-volume operations without sacrificing tolerances or quality |

| Custom/Short-Run Components | Frequent tooling changes for specialized parts |

| High-Precision Components | Aerospace and automotive parts requiring tight tolerances and precise alignment |

This versatility allows manufacturers to consolidate operations, reducing the need for multiple machines and increasing efficiency on the shop floor.

Why Purchasing Through a North American Dealer Matters

Acquiring a C.A.M.S. machine is a significant investment. Partnering with a reliable local dealer ensures both short- and long-term benefits.

Service Support

Local dealers provide:

- Installation and setup support, ensuring machines are operational from day one

- On-site troubleshooting, minimizing downtime

- Preventive maintenance and repairs, extending machine lifespan

Tooling Expertise

C.A.M.S. machines rely on proper tooling for optimum performance. Dealers provide:

- Guidance on broaches, cutters, and inserts for specific part profiles

- Assistance with setup for different materials such as stainless steel, aluminum, and brass

- Recommendations to optimize feed rates, stroke lengths, and tooling angles for consistent results

Localized Supply

Sourcing tooling, consumables, and replacement parts locally ensures fast access and minimal downtime, which is critical for manufacturers adhering to tight production schedules.

ROI Considerations for Precision Manufacturing Shops

Investing in a high-quality slotting machine can significantly impact operational efficiency and cost control. Manufacturers should consider:

- Reduced Scrap and Rework: Precision machining ensures minimal deviations and fewer defective parts

- Lower Labor Costs: Automated NC operations reduce manual intervention, allowing skilled labor to focus on complex tasks

- Increased Production Flexibility: Quick changeovers between part profiles, materials, and tolerances enhance throughput

- Long-Term Reliability: Durable machine construction and local dealer support ensure reduced maintenance costs over the machine’s life

Understanding these ROI factors helps manufacturers justify the initial investment and plan for long-term operational efficiency.

How to Get a Quote and Next Steps

Manufacturers interested in C.A.M.S. slotting machines should follow these steps:

- Assess Production Needs: Determine component sizes, production volumes, materials, and tolerance requirements

- Consult a Trusted Dealer: Broaching Technologies provides expert guidance in selecting the right C.A.M.S. machine model. Explore our Slotting Machines Services page for more details

- Request a Quote: Provide specifications for a customized quote and delivery timeline

- Plan Installation and Training: Ensure your team receives proper training on machine operation, tooling, and maintenance

For detailed inquiries or assistance, please visit our Contact Us page.