Introduction

Selecting the right broaching machine suppliers is a critical decision for manufacturers, OEMs, and procurement managers. The supplier you choose directly impacts machine quality, production efficiency, and overall cost. A reliable supplier ensures your shop operates smoothly, consistently delivers precise components, and has access to ongoing technical support when needed.

Whether you are investing in industrial broaching machines for small parts or high-volume production, choosing the wrong supplier can lead to downtime, costly repairs, or parts that fail to meet specifications. This guide will walk you through evaluating, comparing, and selecting the best broaching machine suppliers, providing actionable tips and insights.

For technical specifications and capabilities of keyway broaching machines, visit Keyway & Spline Broaching Machines Overview.

Why Supplier Selection Matters

Selecting the right broaching machine supplier is more than a purchase decision—it ensures long-term manufacturing efficiency, consistency, and reliability.

Machine Quality and Durability

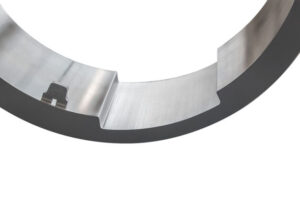

High-quality broaching machines are designed for thousands of precise cuts, reducing maintenance and ensuring reliability for demanding production runs.

Consistency Across Production Runs

Reliable suppliers provide machines that maintain tight tolerances even in large-scale or repetitive manufacturing tasks, which is critical for automotive, aerospace, and industrial applications.

Technical Support and Warranty

After-sales support is essential. The best suppliers offer guidance for setup, troubleshooting, and preventative maintenance, along with warranties for the machinery and tooling.

Features to Look for in a Broaching Machine Supplier

Evaluating potential suppliers ensures you choose one capable of meeting your exact manufacturing needs.

Machine Range and Tooling

Suppliers should offer a comprehensive selection of:

- Horizontal keyway broaching machines for shafts and long components

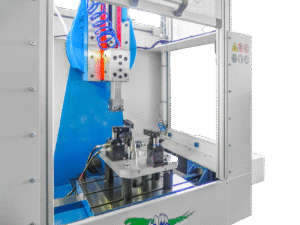

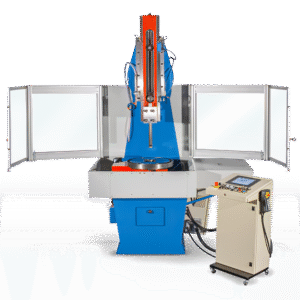

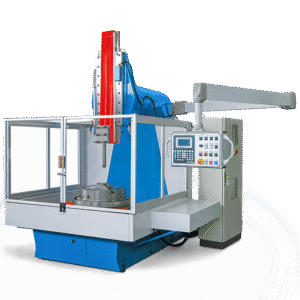

- Vertical keyway machines for compact or specialized parts

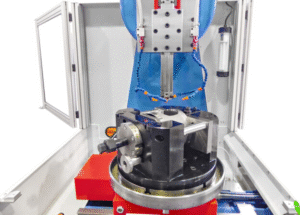

- CNC broaching machines for complex or high-volume operations

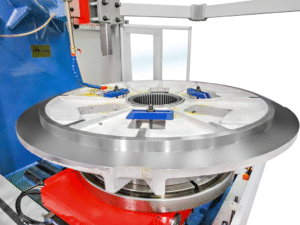

- Specialized tooling for small parts, gears, and internal profiles

Certifications and Industry Standards

Look for ISO certifications, AS9100, or other industry-standard quality certifications. These verify machine reliability and supplier adherence to strict manufacturing standards.

Technical Support and Training

Top suppliers provide installation, operator training, and ongoing maintenance guidance to maximize machine performance.

Customization for Unique Applications

Suppliers who can adapt tooling, machine setup, or controls for specialized components provide significant advantages for complex manufacturing tasks.

Evaluating Broach Manufacturers

Assessing supplier credibility and capabilities is critical.

Reputation and Industry Experience

Suppliers with a proven track record are likely to deliver machines that perform reliably and consistently. Investigate their experience with industries similar to yours.

Case Studies and Client Examples

Review real-world examples to see how suppliers have enabled manufacturers to achieve higher precision, lower scrap rates, or faster production cycles.

Innovation and R&D Capabilities

Suppliers investing in research and development provide advanced features such as:

- Enhanced CNC automation

- Predictive maintenance systems

- Long-life tooling solutions

Local vs Global Suppliers

- Local suppliers may provide faster technical support and easier access to spare parts

- Global suppliers may offer cutting-edge machines or specialized tooling at competitive pricing

Comparing Suppliers Based on Production Needs

Not all suppliers are suitable for every operation. Consider:

Small-Scale vs Large-Scale Manufacturing

- Small operations may prioritize flexibility and affordability

- Large-scale manufacturers need machines capable of continuous high-volume production

Manual vs CNC Machines

CNC machines provide repeatable precision and automation for complex tasks, whereas manual machines are suitable for simpler operations with lower production volumes.

Pricing and Maintenance Contracts

Compare total cost of ownership including machine, tooling, installation, and ongoing maintenance. Prioritize suppliers offering transparent support contracts.

Key Questions to Ask Potential Suppliers

Before finalizing a supplier, ask:

- What is the lead time for delivery and setup?

- Are replacement parts readily available for the machines offered?

- Can you provide custom tooling for specific applications like internal keyways or spline profiles?

- Do you offer operator training for the specific machines purchased?

These questions evaluate a supplier’s reliability, responsiveness, and technical competence.

Common Mistakes in Supplier Selection

Manufacturers often make the following errors:

- Choosing based on price alone: Low cost may compromise quality or precision.

- Ignoring technical support: Poor support can increase downtime and reduce machine life.

- Overlooking compatibility: Ensure the machine meets your component specifications, tolerances, and production volume.

Avoiding these mistakes ensures a long-term, cost-effective solution.

Building Long-Term Supplier Relationships

Strong supplier relationships improve efficiency and reduce operational risk.

Communication and Trust

Open dialogue ensures clarity on machine capabilities, delivery schedules, and technical support.

Maintenance and Service Contracts

Suppliers offering regular maintenance schedules or service contracts help maintain machine precision and longevity.

Collaboration for Process Improvement

Experienced suppliers can advise on tooling optimization, workflow adjustments, and process improvements, enhancing production efficiency.

Case Studies / Examples

Example 1: Automotive Manufacturer

A supplier provided CNC broaching machines tailored for gear shaft production. Results included:

- Improved tolerances by 30%

- Reduced scrap rates by 15%

- Shorter setup times for new production runs

Example 2: Aerospace Component Supplier

Custom tooling and advanced vertical broaching machines enabled high-precision machining of small aerospace parts:

- ±0.02 mm tolerances consistently achieved

- Reduced downtime via predictive maintenance

- Efficient adaptation for complex designs

Future Trends in Broaching Machine Suppliers

- Digital Integration: IoT-enabled machines monitor performance and optimize maintenance schedules.

- Global Sourcing: Manufacturers increasingly source advanced machines internationally to access cutting-edge technology.

- Sustainable Manufacturing: Suppliers offering energy-efficient machines and eco-friendly processes are gaining preference.

Conclusion and Next Steps

Selecting the right broaching machine suppliers ensures precision, reliability, and long-term operational efficiency. Evaluate suppliers based on machine quality, tooling options, technical support, and reputation.

For guidance on choosing the most suitable machines and tooling, consult with our team of broaching specialists or review our detailed Keyway Broaching Machine Selection Guide.