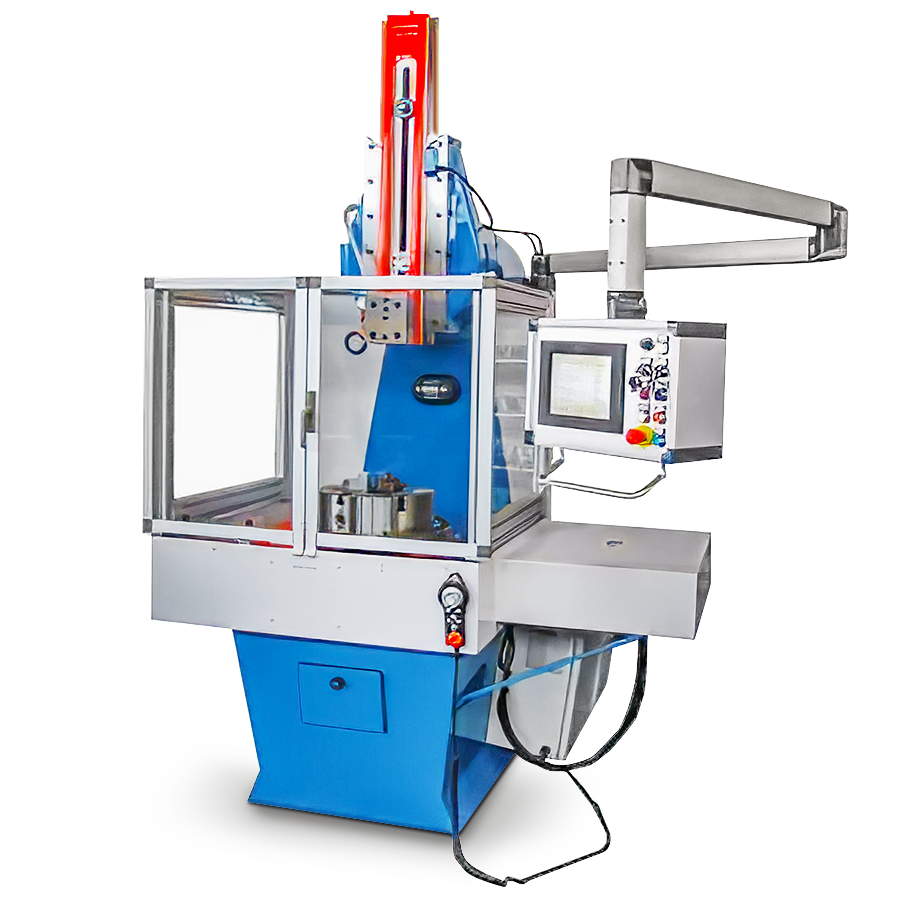

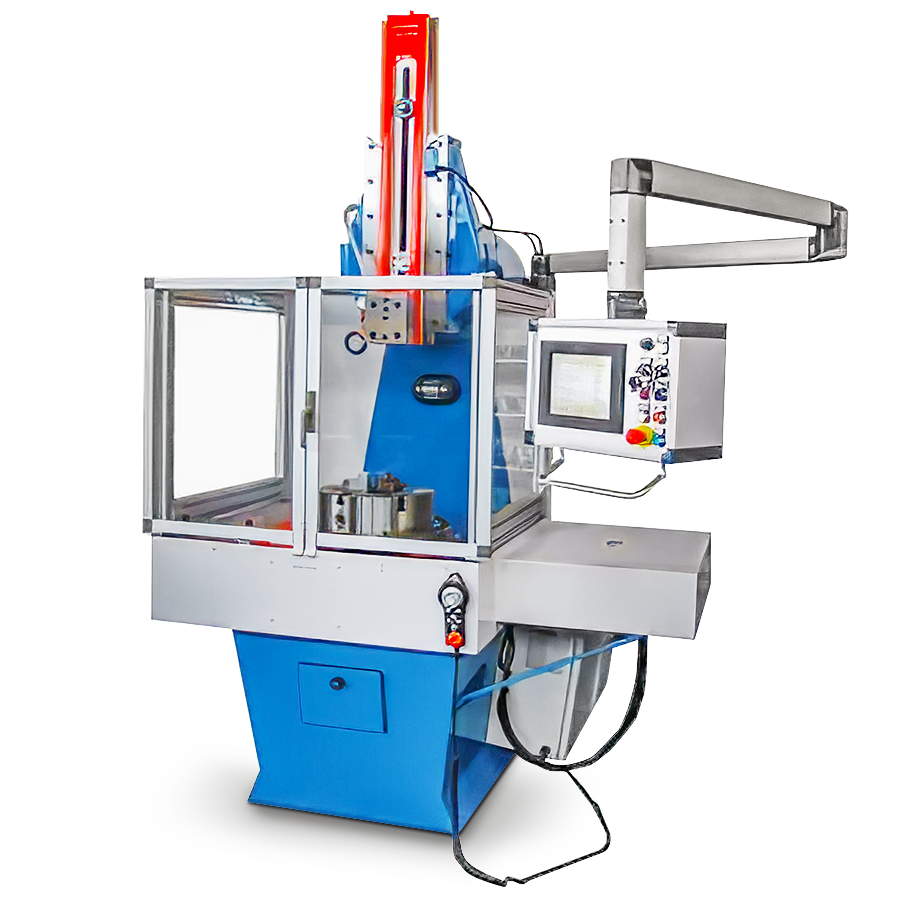

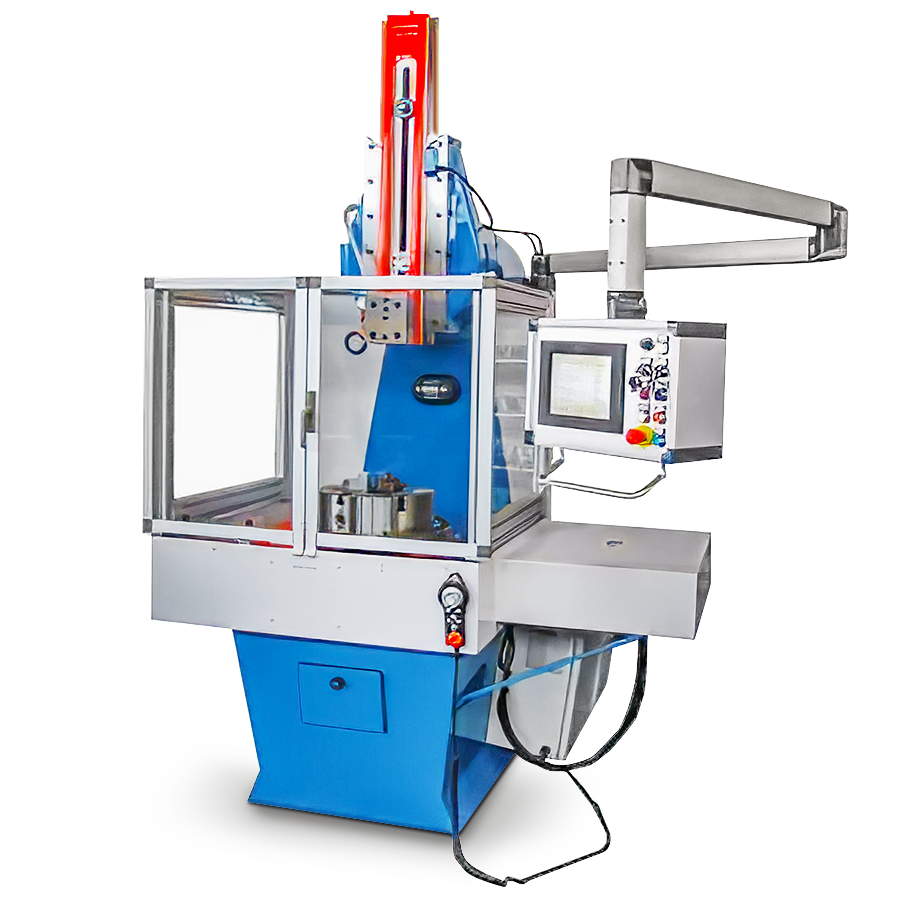

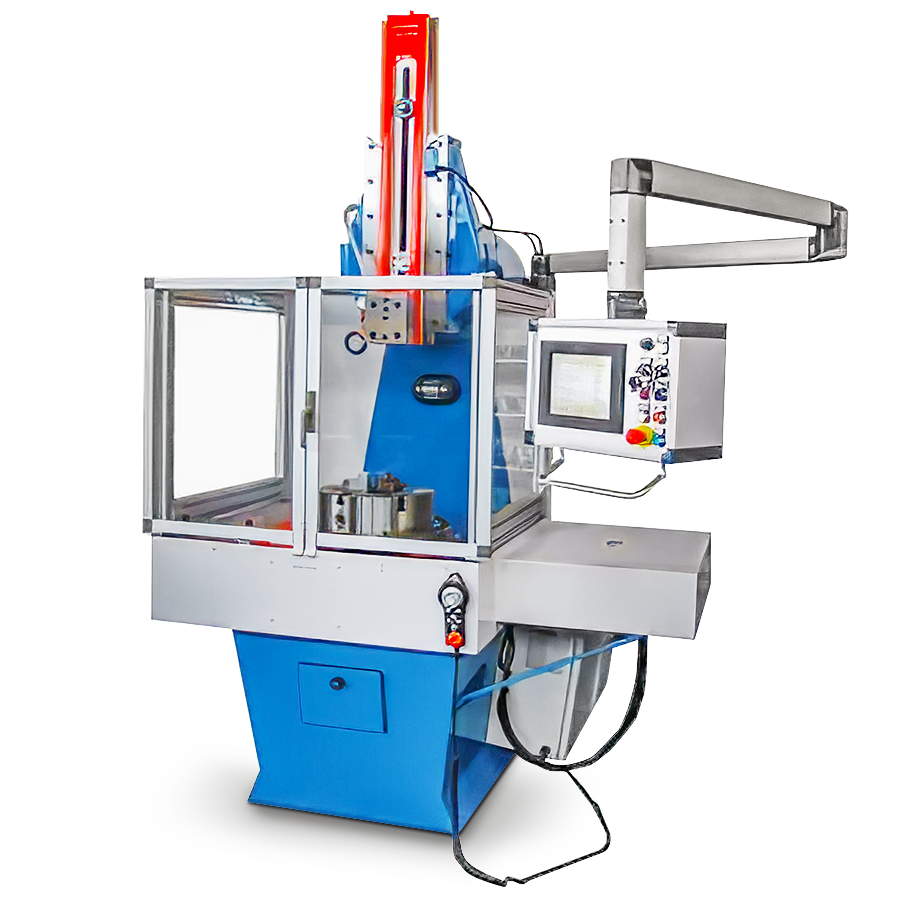

CAMS Vertical Slotting Machines — Precision Engineering for Demanding Applications

Exclusive North American distributor of CAMS slotting machines, engineered in Italy and backed by Broaching Technologies expertise.

About CAMS Slotting Machines

Built in Italy. Supported in America. Proven Worldwide.

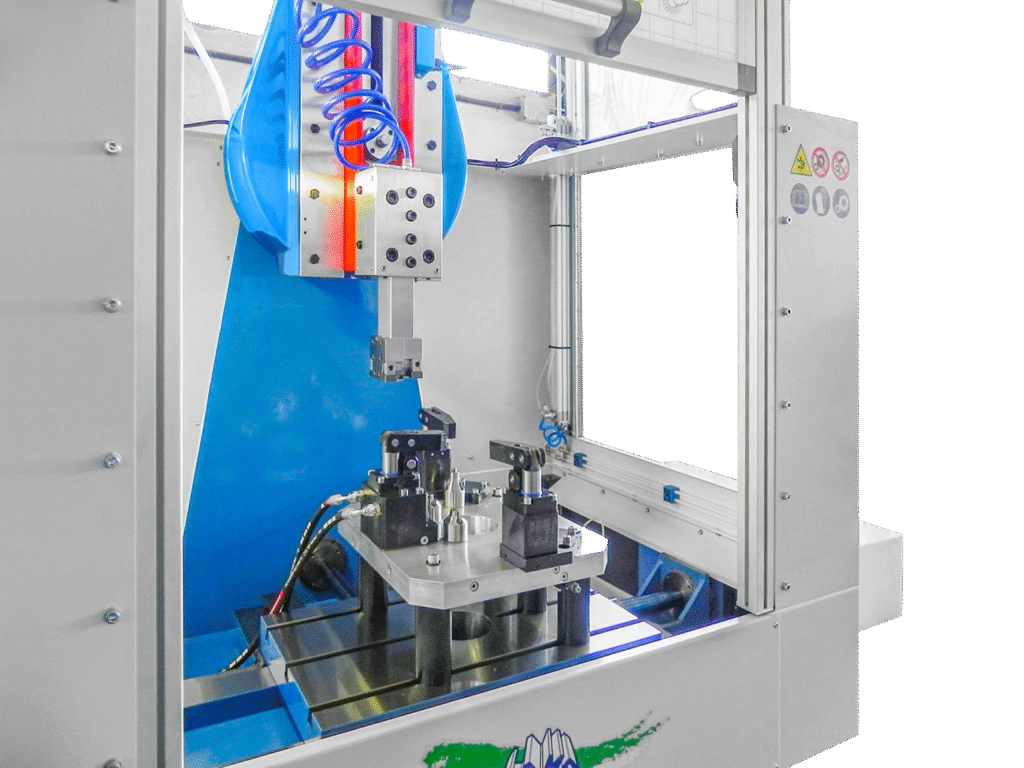

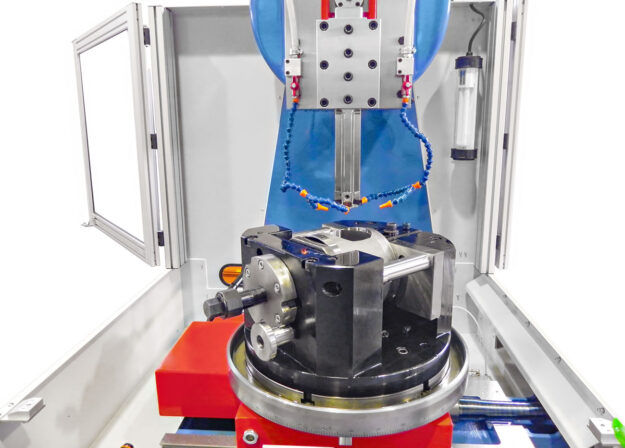

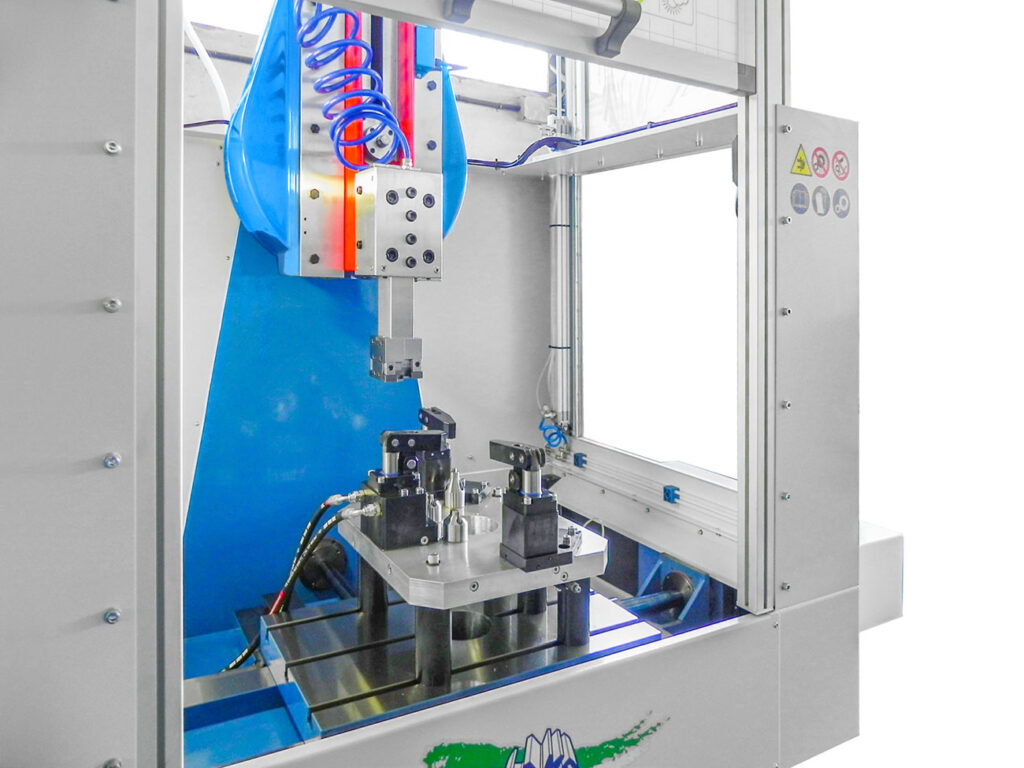

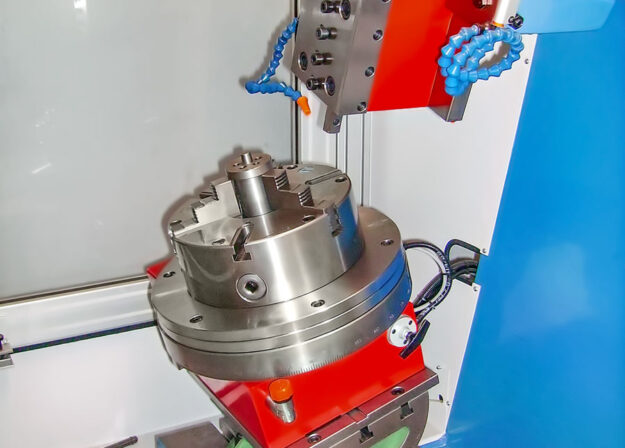

CAMS slotting machines are known globally for their rugged design, CNC control accuracy, and superior surface finish. Manufactured in Italy, these machines combine mechanical rigidity with advanced motion technology — ideal for internal keyways, splines, and complex forms that require both precision and repeatability.

As the Exclusive CAMS Distributor in North America, Broaching Technologies ensures every machine comes with expert guidance, tooling compatibility, and reliable post-sale support.

Choose the Right Machine for Your Application

Whether you’re cutting precision keyways or producing splines in high volumes, there’s a CAMS slotting machine built for your exact requirements. Each model offers incremental advantages in stroke length, workpiece size, and automation level.

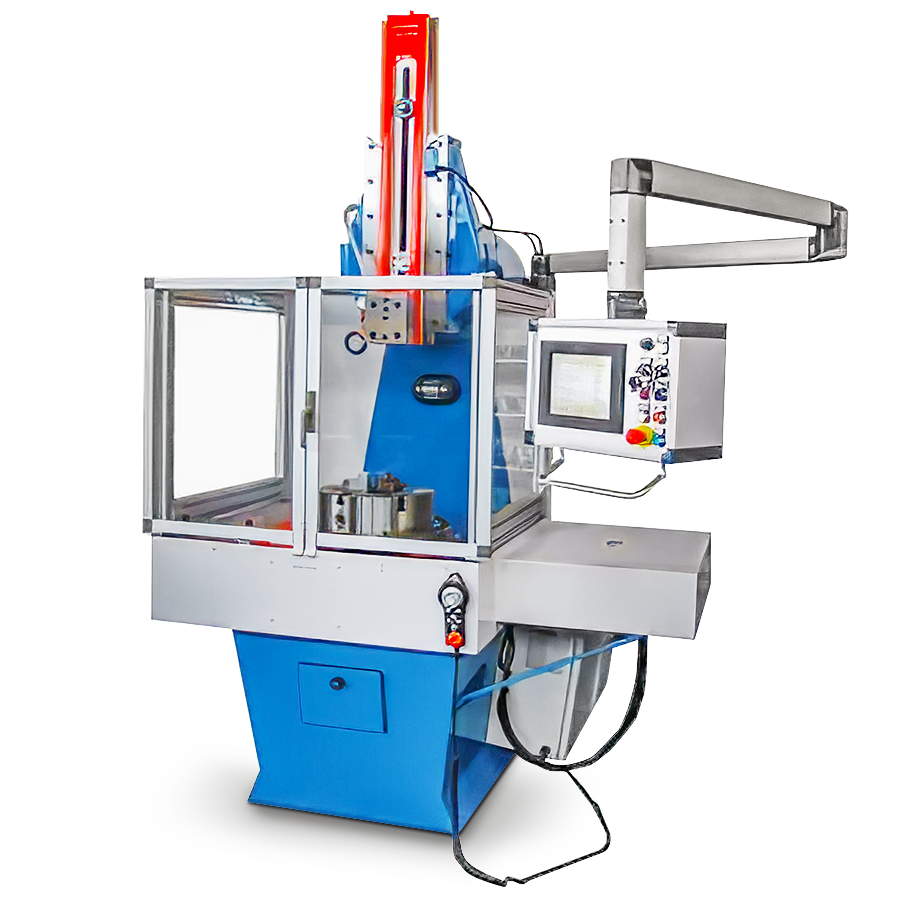

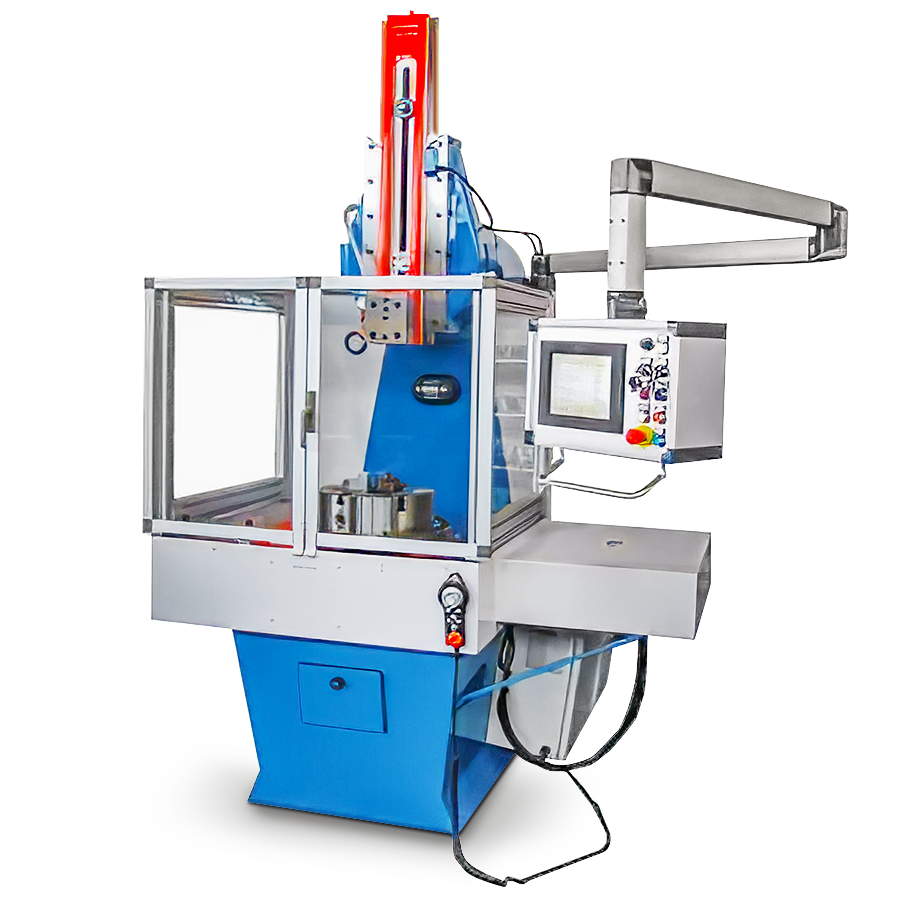

CAMS Slotting Machine 200

Description

Compact entry-level slotting machine designed for small precision parts and light-duty production. Ideal for toolrooms and short-run jobs requiring accuracy and reliability.

Key Specs

Max stroke ≈ 200 mm • Max work Ø 200 mm • 2–3 NC axes (Y-X or Y-X-A) • Tilting head ±20°

CAMS Slotting Machine 250

Description

Mid-size slotter offering greater rigidity and stroke range for moderate production volumes. Perfect for general machining and mid-diameter components.

Key Specs

Max stroke ≈ 250 mm • Max work Ø 250 mm • 2–3 axes NC • Ground cast-iron structure • Tilting head ±20°

CAMS Slotting Machine 300

Description

Versatile machine bridging light and heavy applications. Handles deeper slots and longer components with smooth NC motion control.

Key Specs

Max stroke ≈ 300 mm • Max work Ø 300 mm • 2–4 NC axes (Y-X-A-Z) • Variable speed inverter • Automatic tool lift

CAMS Slotting Machine 350

Description

Larger format slotter built for continuous production. Combines heavy-duty construction with CNC precision for consistent results in medium-to-large parts.

Key Specs

Max stroke ≈ 350 mm • Max work Ø 350 mm • Up to 4 NC axes • Conical slot capability • Closed-circuit cooling

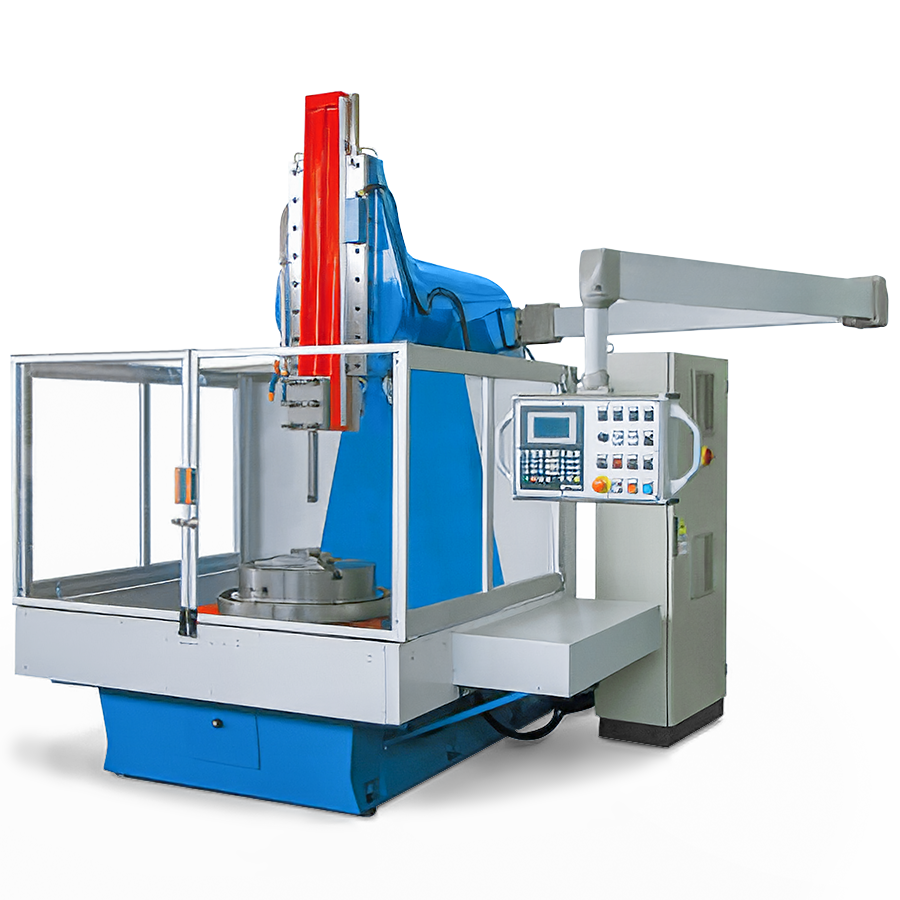

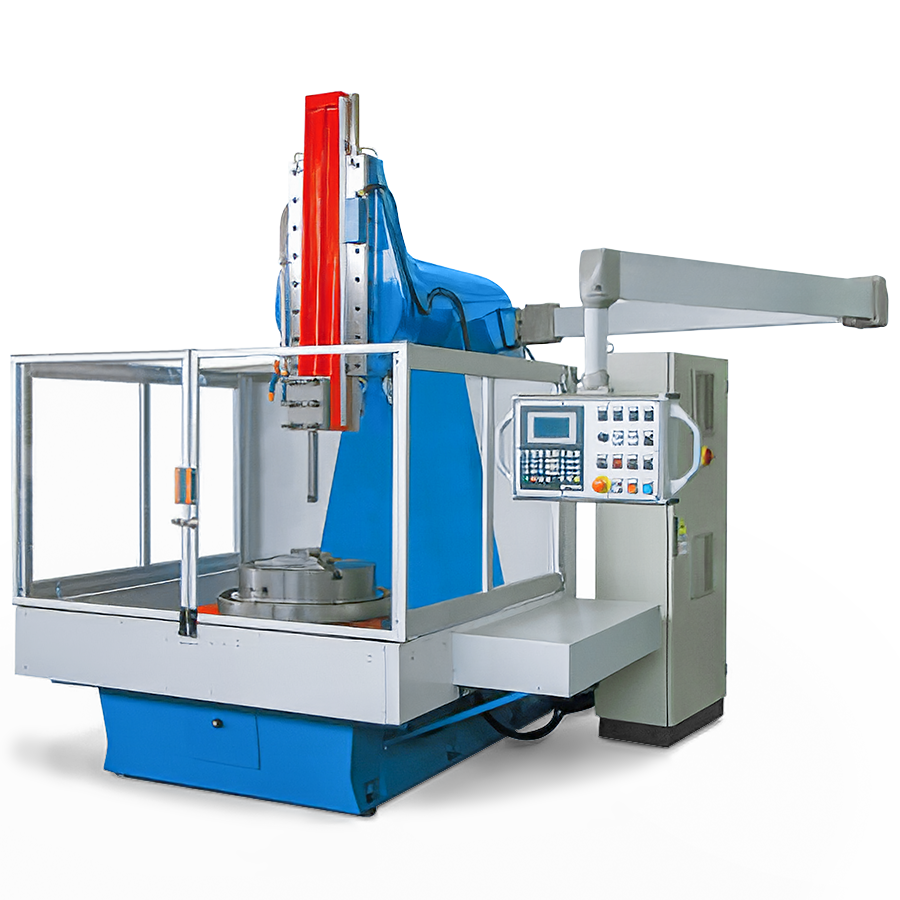

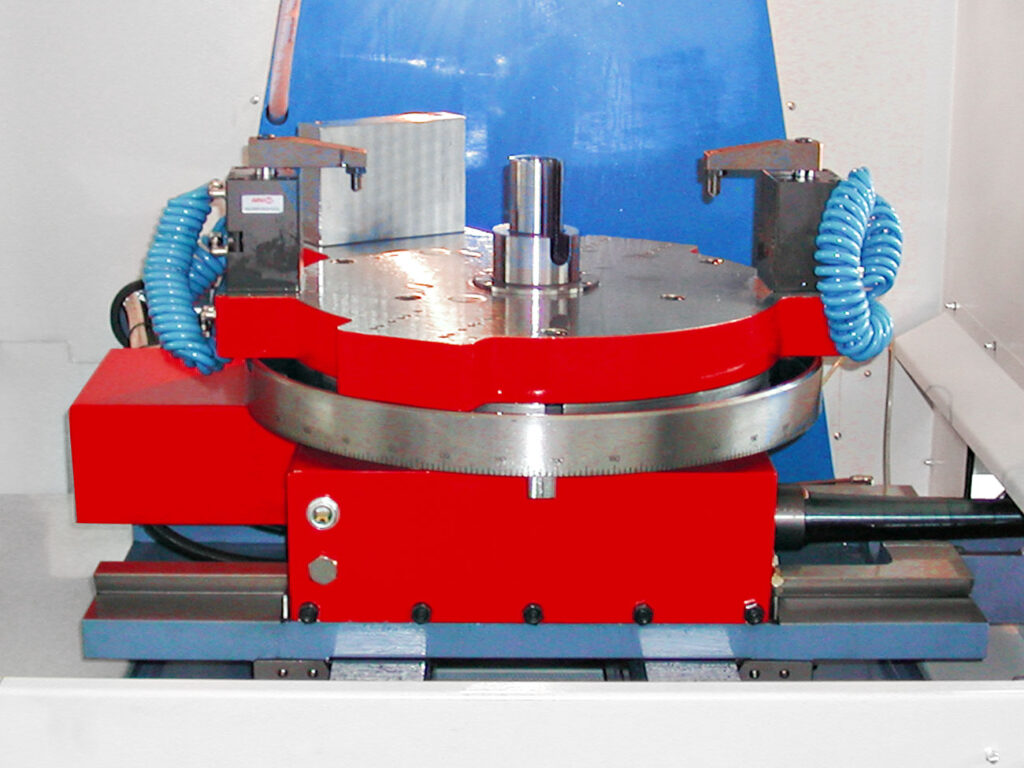

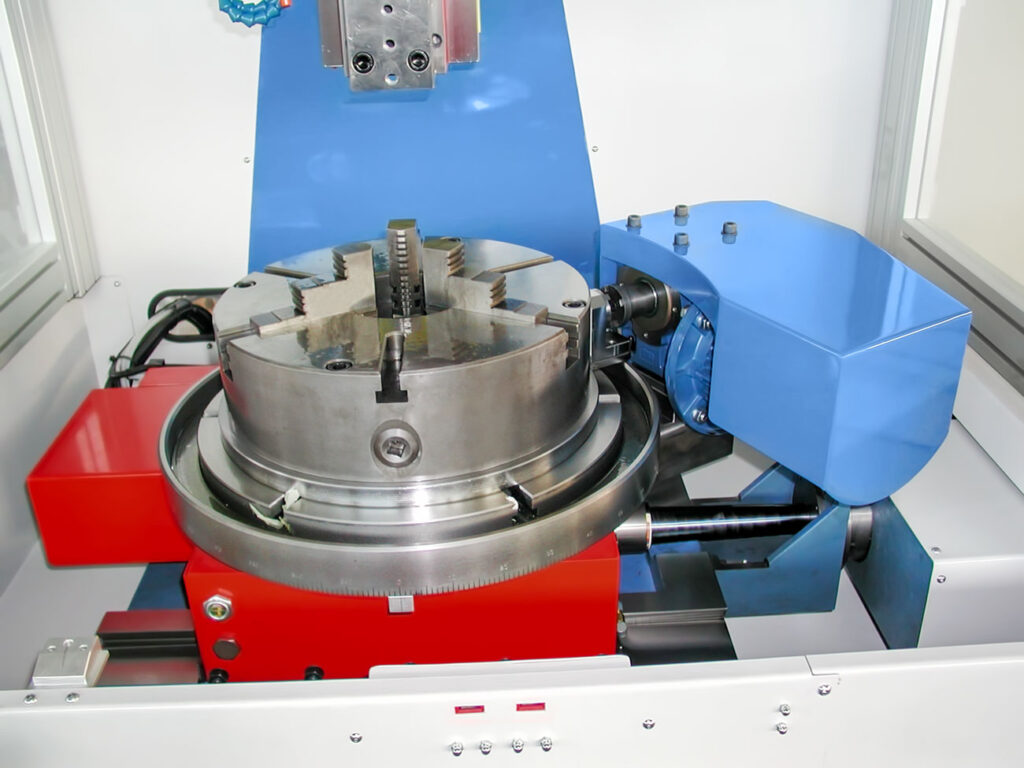

CAMS Slotting Machine 400

Description

Proven production model for long-stroke, high-torque slotting. Accommodates larger shafts and couplings with precise surface finish.

Key Specs

Max stroke ≈ 400 mm • Max work Ø 400 mm • Self-braking motor • Turntable or rectangular table • Tilting head ±20°

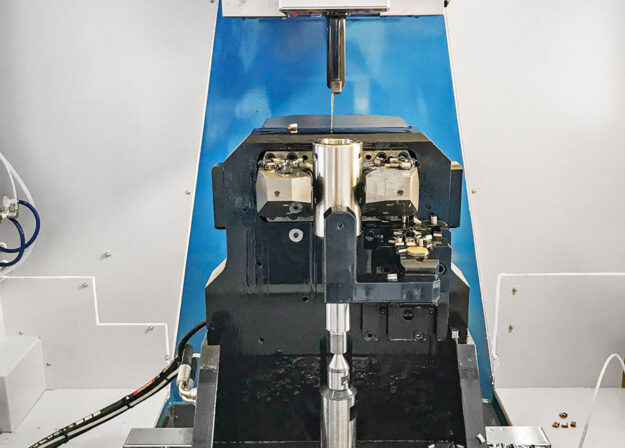

CAMS Slotting Machine 400E

Description

Enhanced 400-series with full 4-axis CNC control for complex internal forms and blind-hole slotting.

Key Specs

Max stroke ≈ 400 mm • Max work Ø 400 mm • 4 NC axes (Y-X-A-Z) • Programmable Z-axis depth control • High-rigidity frame

CAMS Slotting Machine 500

Description

All-around performer for heavy slotting or spline generation. Delivers precise results on hardened materials and long-run production.

Key Specs

Max stroke ≈ 500 mm • Max work Ø 500 mm • Up to 4 NC axes • Tilting head ±20° • Electro-pump cooling system

CAMS Slotting Machine 500E

Description

Electronic variant of the 500 series with extended automation, deeper stroke, and integrated Z-axis control for multi-operation cycles.

Key Specs

Max stroke ≈ 500 mm • Max work Ø 500 mm • 4 NC axes • Programmable tool lift • Automatic lubrication

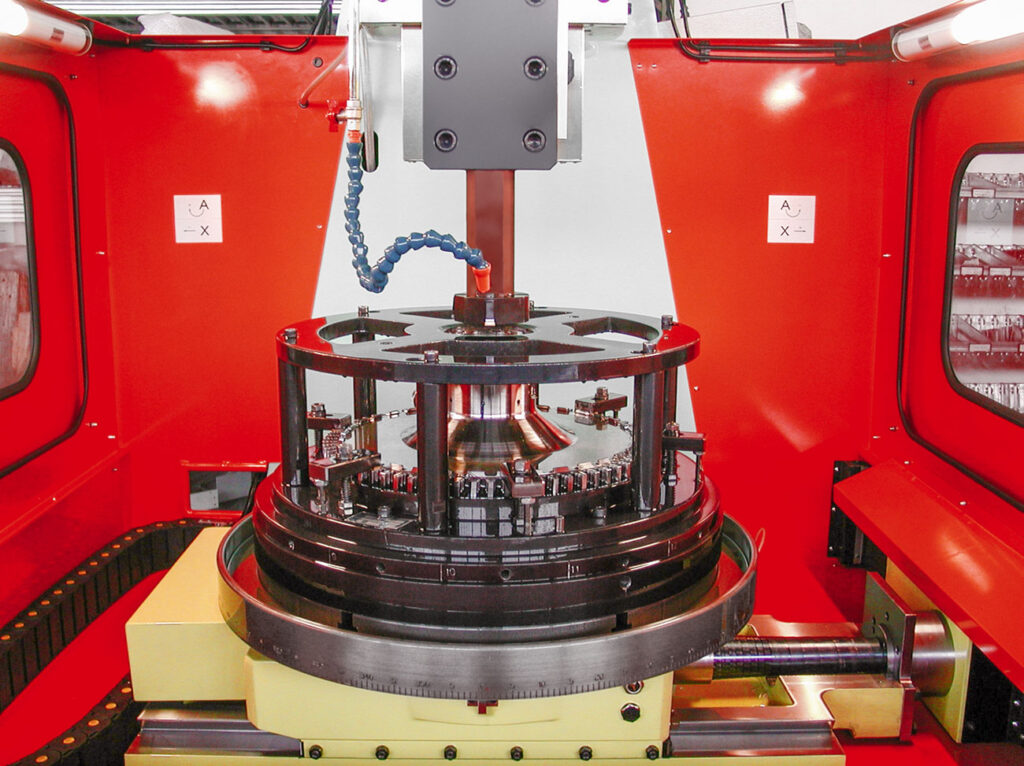

CAMS Slotting Machine 850

Description

Flagship heavy-duty model for the largest, most complex slotting applications. Engineered for aerospace, energy, and industrial gear manufacturing.

Key Specs

Max stroke ≈ 850 mm • Max work Ø 850 mm • 4 NC axes • Electronic turntable (1 500 sym divisions) • Rack-and-pinion ram drive

Custom Slotting Solutions for Specialized Requirements

No two manufacturing environments are alike. Broaching Technologies partners directly with your engineering team to adapt CAMS slotting systems for custom applications.

Our in-house engineering and tooling specialists ensure that every machine is configured for optimal speed, precision, and part quality.

- Blind-hole slotting or spline generation

- Complex internal geometries and deep profiles

- Exotic material handling (Inconel, titanium, stainless)

- Automated or multi-axis part loading

- Integration with existing machining centers

Machine Customization To Meet Your Specific Application

Enhance Performance with Compatible Tooling and Accessories

From precision arbors and fixtures to custom broach tooling designed specifically for CAMS machines, Broaching Technologies provides everything you need to keep your production consistent and efficient.

Our tooling specialists design, sharpen, and recondition tools to maximize machine life and minimize downtime — all backed by decades of broaching experience.

- Custom-designed broach tools and arbors

- Tool holders and alignment fixtures

- CAMS-compatible accessories and parts

- Tool sharpening and reconditioning services

Your North American Partner in Precision Machining

When you invest in a CAMS slotting machine, you gain more than a piece of equipment — you gain a partner. Broaching Technologies has over 30 years of hands-on experience in broaching, slotting, and tooling design. Our team combines technical expertise with a customer-first approach that ensures your success from installation to operation.

30+ years of experience in precision machining

Exclusive CAMS distribution rights for North America

In-house tooling and application support

Proven performance across multiple industries

Ready to Improve Your Precision and Productivity?

Let’s discuss your application and identify the best CAMS solution for your operation. Our engineers will guide you through selection, tooling, and integration to help you get the most from your investment.

Frequently Asked Questions

What is a vertical slotting machine and how does it differ from other machine tools?

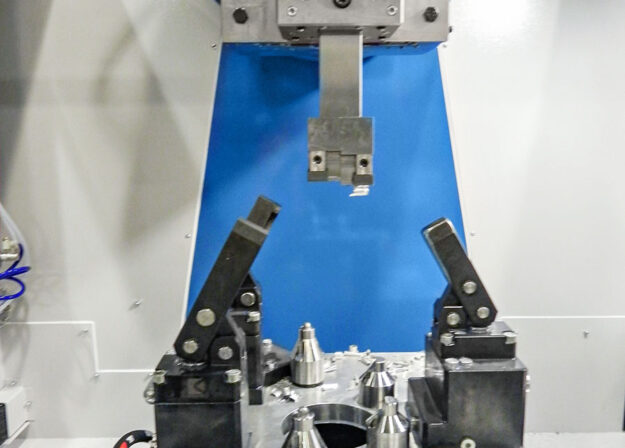

A vertical slotting machine uses a vertically reciprocating ram (tool) to create slots, grooves, or keyways in the workpiece. It is often compared with shapers or planers, but the key difference is the direction of tool travel and the typical use for internal/external slots.

What types of parts can a CAMS vertical slotting machine handle?

These machines are ideal for manufacturing keyways, splines, internal profiles, blind-hole slots, and large diameter workpieces in industries such as automotive, aerospace, power transmission and industrial machinery.

How do you choose the right slotting machine size and model?

Key factors include stroke length (how deep the slotting tool must travel), maximum workpiece diameter, number of NC axes needed, table type (turntable vs rectangular), and material/hardness of the part.

What are the benefits of CNC (multi-axis) slotting machines compared to older manual models?

CNC multi-axis machines offer higher precision, repeatability, ability to machine complex geometries (e.g., conical or internal profiles), lower operator intervention and improved productivity for medium to high volume production runs.

Can slotting machines perform blind-hole and internal slotting operations?

Yes — many modern vertical slotting machines (including advanced models) are configured for blind-hole work, internal grooves, and complex shapes, especially when combined with custom tooling and NC axis configurations.

What tooling and accessories should I plan for when buying a slotter?

Tooling such as broach tools, arbors, fixtures, alignment systems and spares are critical. Also consider machine access, machining material/hardness, lubrication/cooling systems, and reconditioning support.

What maintenance or service considerations should I know for slotting machines?

Pay attention to ram alignment, stroke adjustment, tool lift systems, feed mechanism, lubrication and cooling systems. Proper maintenance ensures longevity, precision and minimizes unplanned downtime.