Introduction

Precision broaching services are a specialized subset of manufacturing processes where high accuracy cutting tools are used to create intricate features in components. Unlike standard broaching, precision broaching is designed for parts that demand tight tolerances, high repeatability, and minimal post-processing.

Manufacturers across industries aerospace, automotive, medical devices, and electronics increasingly rely on these services to produce complex keyways, slots, splines, and internal profiles. By leveraging expert operators, specialized tooling, and advanced machinery, precision broaching services help companies reduce scrap, save production time, and maintain consistent quality without investing heavily in in-house equipment.

In this article, we will explore:

- The process of precision broaching and its differences from standard broaching

- Advantages and types of precision broaching services

- Industries that rely on precision broaching

- Key factors and challenges for achieving high tolerances

- Case studies demonstrating real-world results

- Future trends in the field

- FAQs and expert guidance for engineers and production managers

For machine specifications and tooling details, visit Keyway & Spline Broaching Machines.

What is Precision Broaching?

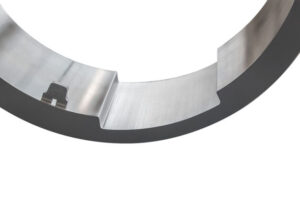

Precision broaching is a linear cutting process where a toothed tool called a broach is pulled or pushed through a workpiece to remove material and create a specific profile. It is particularly suited for high-tolerance, repeatable, and complex components.

Step-by-Step Process

- Workpiece Preparation:

- Components are clamped securely in the broaching machine to avoid movement.

- For metals like stainless steel or titanium, pre-treatment or heat treatment may be applied to achieve optimal machinability.

- Broach Selection:

- Broaches are custom-designed with teeth that progressively cut deeper, creating the desired profile.

- The choice depends on part geometry, material hardness, and desired tolerance.

- Broaching Operation:

- The broach moves linearly (push or pull), cutting the material precisely in a single pass.

- Feed rate, cutting speed, and lubrication are carefully controlled to maintain tolerance and reduce tool wear.

- Inspection and Quality Control:

- Parts are measured using CMM machines, micrometers, or high-precision gauges to ensure compliance with specifications.

- Critical for aerospace, medical, and automotive components where even minor deviations can cause failure.

Difference from Standard Broaching

| Feature | Standard Broaching | Precision Broaching |

| Tolerance | ±0.05–0.1 mm | ±0.01–0.02 mm |

| Application | General parts | High-tolerance components |

| Tooling | Standard broaches | Specialized, hardened broaches |

| Post-Processing | Often required | Minimal required |

| Industry Focus | Industrial, low-spec parts | Aerospace, medical, automotive, electronics |

Materials and Parts Typically Broached

- Metals: Stainless steel, steel alloys, aluminum, titanium, copper alloys

- Parts: Transmission shafts, gear blanks, internal keyways, precision medical implants, miniature electronic components

Precision broaching ensures reliable results for intricate geometries, especially where multiple operations or finishing would increase cost and complexity.

Advantages of Precision Broaching Services

Precision broaching offers several technical and operational benefits:

1. High Tolerances and Consistency

- Produces parts within tight tolerances consistently across large batches.

- Reduces scrap and increases reliability, which is critical for safety-critical or performance-critical components.

2. Reduced Post-Processing

- Accurate broaching minimizes the need for additional machining, grinding, or finishing.

- Saves both time and production costs, especially for complex geometries.

3. Capability to Produce Complex Features

- Blind holes, internal keyways, and spline profiles can be machined precisely.

- Supports miniature components for medical or electronic applications.

4. Cost-Efficiency for Small or Medium Runs

- Precision broaching eliminates the need for expensive in-house machines.

- Outsourcing reduces tooling costs for specialized parts or low-volume runs.

5. Access to Skilled Operators

- Experienced technicians optimize feed rates, lubrication, and broach selection.

- Minimizes errors and ensures repeatable high-quality production.

Types of Precision Broaching Services

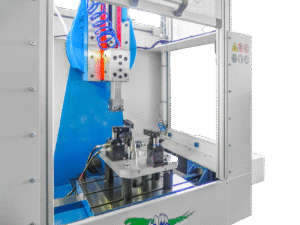

1. Small-Part Broaching

- Suitable for miniature gears, medical implants, and electronic components

- Achieves high repeatability with minimal defects

2. Internal Broaching

- Includes blind hole keyways, internal slots, and hollow profiles

- Ideal for automotive or aerospace components requiring internal precision

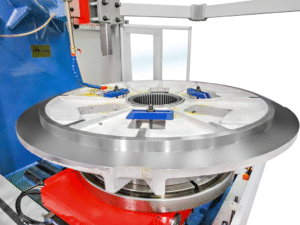

3. Spline Broaching

- Produces involute splines, straight splines, and gear shafts

- Crucial for transmissions, drive shafts, and high-performance gears

4. Custom Broaching Services

- Tailored tooling for unique or prototype components

- Flexible solutions for specialized production requirements

Table: Precision Broaching Services Overview

| Service Type | Typical Applications | Tolerance Range | Industries | Machine Type |

| Small-Part Broaching | Miniature gears, medical devices | ±0.01–0.02 mm | Medical, Electronics | CNC / Manual |

| Internal Broaching | Keyways, blind holes | ±0.01–0.03 mm | Automotive, Aerospace | CNC / Hydraulic |

| Spline Broaching | Shafts, transmission gears | ±0.01–0.02 mm | Automotive, Industrial | CNC / Manual |

| Custom Broaching | Prototypes, unique geometries | ±0.01 mm | Aerospace, Electronics | CNC / Hydraulic |

Industries That Rely on Precision Broaching

Aerospace

- Engine components, turbine shafts, and precision assemblies

- Requires ±0.01 mm tolerance to meet safety and performance standards

Automotive

- Transmission shafts, gears, and couplings

- High repeatability reduces assembly issues and warranty claims

Medical Devices

- Surgical instruments, miniature implants, and orthopedic components

- Accuracy and consistency are critical for patient safety and functionality

Electronics

- Micro-mechanical assemblies, connectors, and precision housings

- Tight tolerances ensure reliable device operation

Key Factors That Ensure Precision

1. Tooling Quality

- Hardened, wear-resistant broaches with specialized coatings (TiN, TiAlN)

- Extends tool life and maintains cutting accuracy

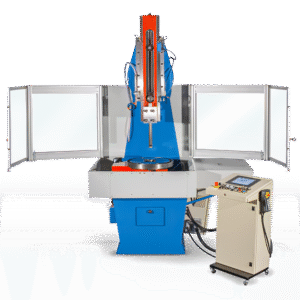

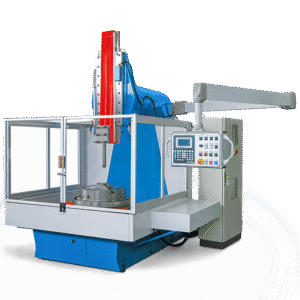

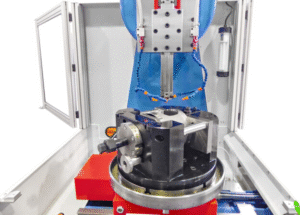

2. Machine Type

- CNC, hydraulic, or manual machines affect precision, speed, and repeatability

- CNC preferred for complex or repetitive production

3. Operator Expertise

- Skilled technicians optimize setup, alignment, and feed rates

- Ensures consistent high-tolerance results

4. Material Hardness and Pre-Treatment

- Hardened metals require optimized cutting parameters

- Pre-treatment reduces tool wear and ensures surface finish and tolerance compliance

Challenges in Precision Broaching

- Maintaining tight tolerances for miniature or complex parts

- Frequent tool replacement due to wear on hard metals

- Handling stainless steel, titanium, or other hard alloys

- Ensuring alignment and accurate feed to avoid defective parts

Contracting precision broaching services mitigates these challenges through advanced machines, tooling, and expert operators.

Case Studies / Examples

Case 1: Aerospace Component

- Component: Small turbine shaft

- Tolerance achieved: ±0.01 mm

- Benefits: Reduced scrap, higher yield, minimal finishing

Case 2: Automotive Gear Shafts

- High repeatability for complex spline profiles

- Reduced production time by 20%, minimized assembly failures

These examples demonstrate precision broaching’s ability to consistently produce high-tolerance parts.

Future Trends in Precision Broaching

- Automation & Industry 4.0: Real-time monitoring, predictive maintenance, and CNC integration

- Advanced Tool Coatings: Long-life, high-performance broaches reducing downtime

- Smart Monitoring: Sensors and feedback loops for tolerance consistency

- Global Outsourcing: Specialized providers enable manufacturers to scale efficiently

Conclusion & Call-to-Action

Precision broaching services enable manufacturers to achieve accuracy, efficiency, and reliability across demanding applications. By outsourcing high-tolerance and small-part broaching, companies benefit from expert operators, specialized tooling, and advanced machines without investing heavily in-house.

For engineers and production managers seeking guidance on precision broaching, internal broaching, or small-part solutions, contact experts at Keyway & Spline Broaching Machines to discuss requirements and request a consultation or quote.