Internal broaching is a cornerstone of precision manufacturing, used in components where torque transfer, alignment, and dimensional accuracy are mission critical. Features such as keyways, splines, and serrations often require tolerances in the sub-micron range. Even minor deviations can propagate during assembly, leading to premature wear, misalignment, or functional failure. Achieving consistent results requires mastery over the entire process, from broach tool design and grinding to in-process control and final inspection.

For engineers and quality managers, understanding how precision is ensured at each stage allows for better design decisions and confident selection of broaching services. A well-structured broaching process ensures parts meet stringent specifications while minimizing scrap, reducing downtime, and extending tool life.

Introduction — Why Broaching Demands Extreme Accuracy

Broaching is more than a simple cutting operation; it is a highly controlled, precision process. In applications like aerospace gear housings, hydraulic components, and electric vehicle motors, even slight misalignments in internal features can compromise assembly performance. The accuracy of a broached keyway or spline directly affects torque distribution, load-bearing capacity, and component longevity.

The complexity arises because broaching is a single-stroke process, where multiple teeth engage the material progressively. Each tooth removes a small amount of material, but the cumulative effect can produce deviations if tooling or process parameters are not tightly controlled. Factors such as tool geometry, feed rates, machine rigidity, thermal expansion, and lubrication all play pivotal roles in achieving high-quality finishes. Vendors with expertise in these areas can maintain consistent tolerances while reducing the likelihood of defects or rework.

The Foundation: Proper Broach Tool Design

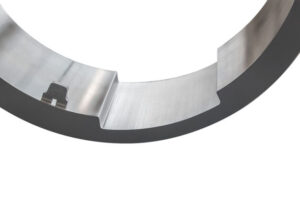

Tool design forms the foundation of precision in broaching. The geometry of the broach, including rake and relief angles, hook angle, and tooth progression, directly influences cutting efficiency, surface finish, and dimensional stability. For example, the rake angle determines how the chip flows and how much cutting force is exerted on the workpiece, while the relief and land provide support to the cutting edge without introducing excessive friction. The hook angle, tooth height progression, and chip gullet design are critical for maintaining control in blind keyways or long splines, where chip evacuation and progressive load distribution are essential.

The material and coating of the broach also matter. High-speed steel (HSS) remains popular for small runs or soft materials, offering toughness and moderate wear resistance. Carbide broaches are favoured for high-volume or abrasive applications because of their superior hardness and thermal stability. Coatings such as TiAlN or diamond-like carbon reduce friction, resist heat, and extend tool life, ensuring consistent performance even when broaching challenging materials like stainless steel.

Complex profiles, such as blind keyways or combination splines, often require custom broaches. These tools are designed with progressive tooth heights and specialized gullet shapes to reduce the risk of tool deflection and ensure accurate internal feature formation. Key considerations in tool design include:

- Tooth progression tailored to part geometry

- Relief angles optimized for material type

- Chip evacuation paths to prevent jamming

Broach Tool Grinding — The Heart of Precision

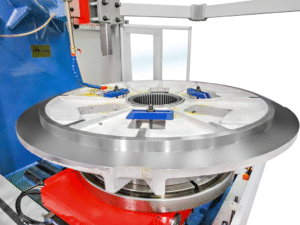

Grinding the broach is a critical step that directly impacts its performance. Form grinding creates the precise tooth profile, whether involute, parallel, or serration types. Maintaining flank accuracy is essential to avoid backlash or uneven load distribution. Techniques like careful wheel dressing and controlled grinding depth ensure that each tooth matches the intended design specifications.

Surface grinding ensures the broach body is flat, parallel, and perpendicular where required, which stabilizes the broach during cutting and reduces vibration-induced errors. Regrinding cycles are also necessary; broaches experience wear over time, particularly when cutting hard or abrasive materials. Advanced vendors monitor tool wear through dimensional checks, observing the performance of the broach in cutting tests, and using specialized measurement equipment.

Some of the key grinding considerations include:

- Accurate tooth profile formation to match CAD specifications

- Wheel dressing for consistent geometry

- Surface flatness for machine stability

In-Process Controls During Broaching

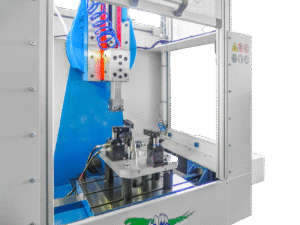

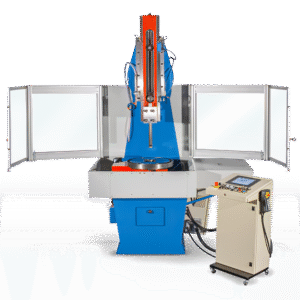

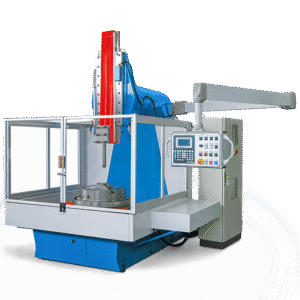

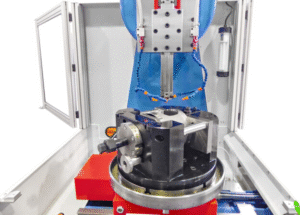

Achieving precision in broaching extends beyond tool design and grinding; it requires careful in-process control. Proper fixturing aligns the bore to prevent deflection, while machine rigidity ensures stable cutting even in high-load conditions. Blind or long keyways require additional support to avoid end-wall distortion.

Feed, speed, and load parameters are continuously monitored and adjusted. Different materials behave differently: stainless steel work-hardens and generates heat, aluminium tends to smear, and brass can overcut if feed rates are too high. Machines equipped with load sensors detect resistance changes during cutting, allowing real-time adjustments to maintain dimensional accuracy.

Cooling and lubrication also play a critical role. Coolants remove heat, reduce friction, and improve chip evacuation. Material-specific lubricants are necessary for optimal performance, especially when broaching soft or ductile metals. Real-time monitoring systems track load, torque, and stroke to ensure process stability. Automated corrections prevent excessive tool wear and maintain consistent tooth engagement, while logged data supports continuous process improvement and parameter optimization.

Inspection Methods That Guarantee Accuracy

Inspection is an integral part of the broaching process. Coordinate Measuring Machines (CMMs) capture full 3D profiles of keyways and splines, enabling involute verification and dimensional comparisons with CAD models. Air gauging is ideal for high-speed production runs, allowing rapid verification of tight tolerances. Optical profile projectors provide magnified views of serrations and micro-profiles, ensuring each tooth meets specifications. Go/no-go gaging is a fast, reliable method for volume production, confirming critical dimensions efficiently.

A comprehensive inspection workflow often includes:

- First-article inspection to verify initial production pieces

- Statistical process control (SPC) to track deviations over time

- Documentation and certification of materials, tolerances, and measurement results

These methods collectively ensure repeatable, reliable results for high-precision internal broaching.

Why Working with a Skilled Broaching Vendor Matters

Precision in broaching is not accidental; it results from the combination of tool design, grinding, process control, and inspection. A skilled vendor ensures that parts meet strict tolerances consistently, reducing scrap and improving assembly fit. Properly executed broaching extends component life, ensures reliable torque transmission, and supports repeatable high-volume production.

Vendors with expertise in materials, tooling, and inspection processes can also provide guidance during the design stage, ensuring manufacturability and optimal performance from the start. The ability to adapt tooling, optimize feed rates, and select appropriate coatings for specific materials is what differentiates high-precision vendors from standard suppliers.

Conclusion

Precision and quality in broaching are achieved through a holistic process. Every stage, from tool design to grinding, in-process monitoring, and final inspection, contributes to achieving sub-micron tolerances, consistent surface finish, and reliable part performance. Engineers benefit from understanding these processes to specify accurate, manufacturable components and select capable vendors. A competent broaching partner ensures that internal features such as keyways, splines, and serrations meet functional requirements while maintaining process efficiency, repeatability, and part longevity.

For expert guidance on your broaching requirements or to discuss how we can help with precision keyways, splines, and serrations, contact us today.