Slotting machines play an essential role in modern workshops, offering precision and consistency in machining grooves, keyways, and internal profiles. Among the popular choices, CAMS slotting machines are widely recognized for their engineering quality, reliability, and ability to handle varied workloads. But with multiple models available—such as the CAMS 200, CAMS 400E, and CAMS 500—selecting the best fit for your shop can be a challenge.

This comprehensive guide walks you through the process of choosing the best CAMS slotting machine model for your needs. It covers slotting capacity, tooling options, accessories, and long-term considerations so that your investment delivers value for years to come.

Understanding Slotting Machines

Before comparing models, it’s important to understand what a slotting machine does. Slotting machines are designed to cut vertical or inclined slots into a workpiece. These slots can serve many purposes, including:

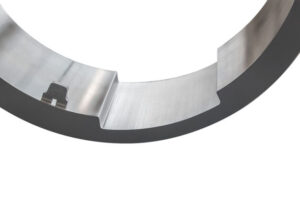

Creating keyways inside gears or pulleys

Machining splines for mechanical transmission

Producing rectangular or irregular grooves

Preparing components for assembly in larger systems

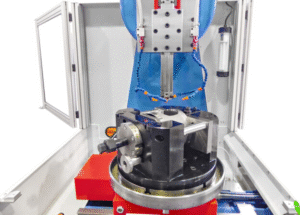

In essence, a slotting machine bridges the gap between milling and shaping processes, offering unparalleled precision for internal machining operations.

Why CAMS Machines Are Popular in Workshops

CAMS slotting machines have earned a reputation for combining durability with accuracy. Workshops often prefer CAMS models for reasons such as:

Precision engineering – Each model delivers consistent results for critical applications.

Range of models – From smaller units for light jobs to heavy-duty machines for industrial work, there is a solution for every shop size.

Flexibility with tooling – Compatibility with a wide variety of cutters makes them adaptable to evolving shop requirements.

Robust construction – Designed for longevity, CAMS machines perform reliably even under demanding production schedules.

Key Factors to Consider Before Selecting a CAMS Model

When evaluating the best CAMS slotting machine model for your shop, it’s important to look beyond the headline specifications. Here are some general factors to guide your decision:

1. Slotting Capacity

Slotting capacity refers to the maximum stroke length and the size of workpieces that a machine can handle. Smaller models are suitable for precision parts, while larger models are better suited for heavy, industrial components.

2. Workload and Production Volume

A shop producing custom or low-volume parts may not need the largest machine available. On the other hand, continuous production facilities require higher-capacity machines to avoid bottlenecks.

3. Tooling Options

The flexibility of tooling determines how well the machine can adapt to different jobs. Consider whether the model supports a wide range of slotting cutters and holders.

4. Accessories and Upgrades

Optional accessories like digital readouts, indexing tables, and lubrication systems can make a significant difference in productivity. Choosing a model that offers future upgrade paths can help your shop stay competitive.

5. Ease of Operation

User-friendly controls, ergonomic design, and straightforward maintenance routines reduce operator fatigue and enhance productivity.

6. Budget and Long-Term ROI

The initial investment is just one part of the equation. Factoring in maintenance, energy consumption, and downtime helps calculate the machine’s real return on investment.

Overview of CAMS 200, CAMS 400E, and CAMS 500

CAMS offers a range of models to suit different shop sizes and production demands. Among the most discussed are the CAMS 200, 400E, and 500. Each has its strengths and limitations.

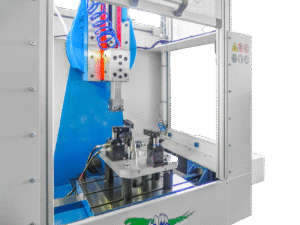

CAMS 200

The CAMS 200 is best suited for smaller workshops or those focusing on precision parts. It offers:

Compact design for limited space

Excellent precision for keyways and small splines

Lower slotting capacity compared to larger models

Ideal for light to medium workloads

This machine is often chosen by shops that work with small to medium components but require accuracy above all else.

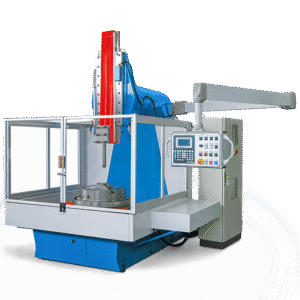

CAMS 400E

The CAMS 400E is a versatile option designed for medium-scale operations. It provides:

Balanced capacity and precision

Ability to handle medium to large parts

Compatibility with a broader range of tooling

Support for additional accessories and upgrades

This model is a good fit for workshops that anticipate growth or handle a wide variety of components.

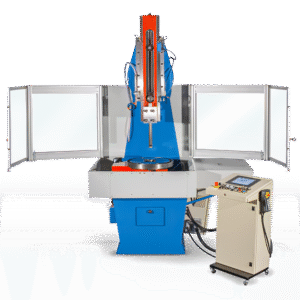

CAMS 500

The CAMS 500 represents the heavy-duty end of the spectrum. Its features include:

High slotting capacity for large and heavy parts

Rugged construction for industrial workloads

Compatibility with advanced tooling systems

Full support for automation and productivity accessories

It is ideal for industries such as aerospace, automotive, and heavy equipment manufacturing, where efficiency and consistency are critical.

Tooling and Accessories for CAMS Machines

The performance of a slotting machine is closely tied to the tooling and accessories used. CAMS models support a range of options:

Tooling Options

Standard cutters for general-purpose slotting

Specialty cutters for unique profiles

Multi-tooth cutters for higher throughput

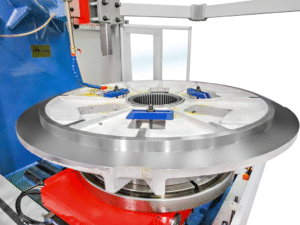

Accessories

Indexing tables for machining multiple slots at precise angles

Digital readouts for real-time accuracy monitoring

Lubrication systems to reduce wear and extend machine life

Coolant systems for managing heat during intensive jobs

Choosing the right combination of tooling and accessories ensures maximum flexibility and long-term value.

Evaluating Slotting Capacity in Practice

Slotting capacity is more than just a number. It defines how effectively a machine can handle your typical workload. Consider:

The size and weight of your most common parts

The required stroke length for your applications

Whether you need shallow precision cuts or deep, heavy-duty slots

Matching capacity to requirements prevents overinvestment in unused features or underperformance during peak workloads.

Maintenance and Longevity of CAMS Machines

A significant advantage of CAMS machines is their durability. However, proper maintenance is essential:

Regular lubrication prevents wear on moving parts

Coolant system checks help maintain cutting efficiency

Alignment inspections ensure accuracy over time

Tooling care extends cutter life and maintains precision

By following preventive maintenance routines, shops can extend machine lifespan and reduce downtime.

Long-Term Investment Considerations

When comparing models, think about how your business might evolve in the next five to ten years. A machine that seems more expensive initially could prove cost-effective by:

Reducing setup time with better accessories

Handling a wider range of part sizes

Supporting automation for future expansion

Lowering per-part production costs through efficiency gains

Conclusion

Choosing the best CAMS slotting machine model is a strategic decision that depends on your shop’s size, production volume, and future goals. The CAMS 200 excels at precision work for smaller shops, the CAMS 400E provides versatility for growing operations, and the CAMS 500 offers industrial-scale performance for demanding environments.

By carefully evaluating slotting capacity, tooling options, and long-term ROI, shop owners and purchasing teams can select a machine that not only meets their current requirements but also supports future expansion. For more details on CAMS machines and specialized tooling, you can explore slotting machine options or discuss your needs with experts through their contact page.