In precision manufacturing, internal broaching plays a crucial role in producing highly accurate and durable components. When designers and engineers specify parts, the choice between blind keyway broaching vs through keyway can significantly impact part performance, manufacturability, cost, and tool longevity. Selecting the wrong keyway type can lead to excessive tool wear, poor surface finish, or structural weaknesses. Understanding the nuances of blind and through keyways is particularly critical in industries like aerospace, electric vehicle motors, hydraulic components, and gear manufacturing. The decision depends not only on the part geometry but also on broach design, machine capability, and material characteristics. Companies offering internal broaching services specialize in optimizing these factors to meet stringent engineering standards.

Introduction: Why Keyway Type Matters in Precision Manufacturing

Keyways are slots machined into a bore to accommodate a mating key, which transmits torque between components such as shafts and hubs. Choosing between a blind or through keyway is more than a geometric preference.

- Performance: The keyway type affects torque transmission, stress distribution, and part longevity.

- Manufacturability: Blind keyways require more complex tooling and process planning, while through keyways are generally easier to produce.

- Cost & Tool Life: The wrong choice increases tooling costs, leads to higher scrap rates, and reduces productivity.

Industries such as aerospace, EV motor production, hydraulic systems, and precision gear manufacturing face unique challenges that make the distinction between blind and through keyways critical.

Blind Keyway Broaching — Definition, Function & Engineering Requirements

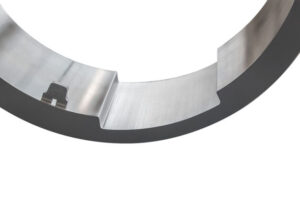

What Is a Blind Keyway?

A blind keyway is a slot that stops short of exiting the bore. This configuration is used when one face of a component must remain intact for structural or assembly reasons. Key engineering considerations include:

- Maintaining torque transfer efficiency without compromising the end wall.

- Avoiding stress concentrations that could weaken the part.

- Size limitations, as very deep or narrow blind pockets can be challenging to machine accurately.

Why Blind Keyways Are More Challenging to Broach

Blind keyways are more technically demanding due to:

- Restricted chip evacuation, which can cause chip compaction and tool breakage.

- Higher cutting pressure at the blind end, increasing risk of tool deflection.

- Heat accumulation in the pocket, which may impact tolerances and surface finish.

- Potential surface tearing or end-wall distortion, requiring precise tooth geometry and lubrication management.

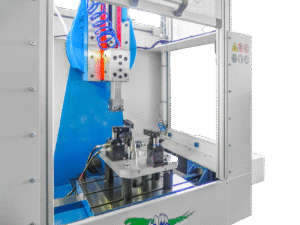

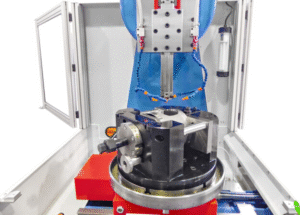

Step-by-Step Blind Keyway Broaching Process

- Fixturing: The blind end must be properly supported to prevent deflection.

- Progressive Cuts: Broach teeth are designed for stepwise material removal to manage cutting forces.

- Tooth Geometry: Specialized end teeth reduce stress and allow chip compression.

- Debris Management: Chips are compacted within the pocket, necessitating advanced lubricants and cutting fluids.

Typical Applications of Blind Keyways

- Electric motor housings where the rear surface is critical

- Gear hubs requiring structural integrity at the back face

- Precision couplings in industrial machinery

- Aerospace components with stringent tolerance requirements

Through Keyway Broaching — Simplicity, Strength & High-Throughput Benefits

Definition & Functional Advantages

A through keyway passes entirely through the bore, allowing for an open exit. Advantages include:

- Simplified chip removal

- More consistent surface finish

- Reduced cutting forces at the exit, which minimizes tool stress

Through Keyway Broaching Process Breakdown

- Standard broach tools can be employed with minimal custom modifications.

- Tool stroke optimization allows for faster cycle times.

- Open-ended slots reduce the risk of tool wear and end-wall defects.

Cost Advantages of Through Keyways

Through keyways often reduce broaching costs because:

- Tooling is simpler and more standard

- Rework and scrap rates are lower

- Higher repeatability supports large production volumes

Common Applications

- Pulleys and sprockets

- General industrial shafts

- Automotive production with high-volume throughput

Technical Comparison — Blind vs Through Keyway

| Feature | Blind Keyway | Through Keyway |

| Tooling Complexity | High, requires custom tooth geometry and relief angles | Standard tools, simpler design |

| Chip Evacuation | Challenging, risk of jamming | Open path, easy chip removal |

| Surface Finish | Higher risk of rough end wall | Cleaner exit plane, better finish |

| Cutting Forces | Higher at blind end | More uniform, lower overall |

| Heat Management | Critical due to trapped heat | Easier to manage with fluid flow |

| Tolerance Capability | Limited by depth and bore diameter | Higher, more consistent |

Tooling Differences

Blind keyway tools require advanced relief geometry, specialized rake angles, and optimized chip gullets. Through keyways can utilize standard broach designs, reducing custom tooling costs.

Cutting Forces & Heat Management

Blind pockets trap heat, affecting tolerances. Coatings like TiN or TiAlN help manage thermal loads. Through keyways allow fluid to evacuate heat efficiently.

Surface Finish Impacts

Blind pockets often result in rough end-wall finishes, while through cutting provides a clean, uniform surface.

Tolerance Capability Differences

- Blind keyways are limited by concentricity, bore size, and length-to-diameter ratios.

- Through keyways support higher precision, even in long keyways or internal spline broaching.

Chip Evacuation Constraints

Blind keyways require careful chip management to avoid jamming and tool failure, often employing peck broaching techniques or specialized lubricants.

Material Considerations — Stainless Steel, Aluminium, Brass & More

Stainless Steel

Work-hardening and chip adhesion make blind broaching challenging. Tool life must be closely monitored.

Aluminium

Blind pockets risk smearing. Polished cutting edges and proper lubrication are critical.

Brass

High machinability allows for easier broaching, but care is needed to avoid overcutting near the blind end.

Carbon Steel

Balances machinability and strength, though tool life may need adjustment for blind pockets.

When to Choose Blind vs Through Keyway — Engineering Decision Criteria

Engineers should weigh several factors:

- Geometric limitations: Depth, bore size, and wall thickness

- Structural integrity: Need to maintain end-wall strength

- Cost vs manufacturability: Tooling and process complexity

- Production volume: Through keyways Favor high-volume runs

- Tolerance and finish requirements

- Assembly considerations: Part alignment and mating components

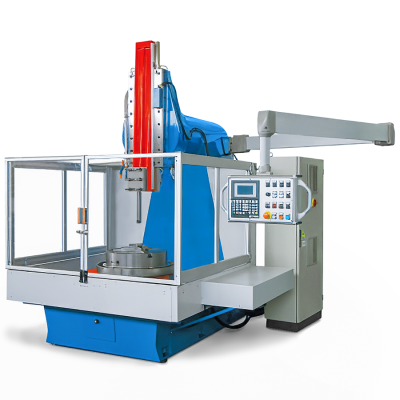

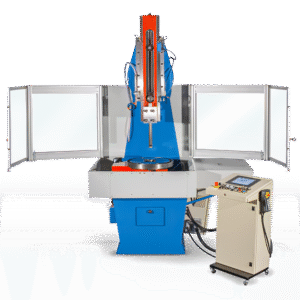

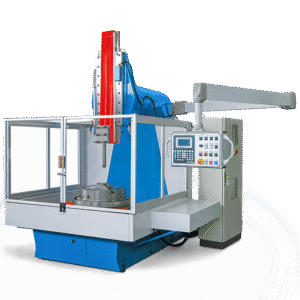

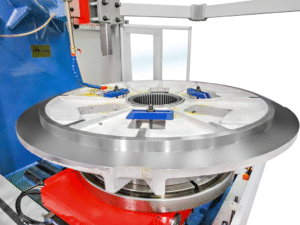

How Internal Broaching Services Optimize Each Process

Professional internal broaching services enhance outcomes by:

- Custom tool design to match part geometry

- Adaptive broaching parameters for optimal cutting forces and chip management

- Automated inspection for tolerance and surface finish validation

- Secondary operations like deburring and lapping to improve assembly readiness

Conclusion

Choosing between blind keyway broaching vs through keyway is a nuanced engineering decision. It affects part performance, cost, and manufacturability. Blind keyways require specialized tooling, careful chip management, and precise process control, while through keyways offer efficiency, repeatability, and lower risk of defects. Early collaboration between designers, engineers, and internal broaching services ensures optimal outcomes for any precision manufacturing project. For technical support or service inquiries, contact us to discuss your part requirements.