Introduction

A keyway broaching machine is an essential piece of equipment in modern manufacturing, widely used for cutting keyways, slots, and internal profiles into shafts, gears, and mechanical components. These machines allow manufacturers to produce parts with high precision and repeatability, making them indispensable in industries like automotive, aerospace, and industrial machinery.

For more information about industrial machinery and broaching services, you can visit us. In this guide, we will explore how keyway broaching machines work, the different types available, their tooling, applications, and how to choose the right machine for your production needs.

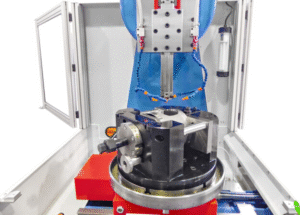

How Keyway Broaching Machines Work

A keyway broaching machine operates by pulling or pushing a broach tool through a workpiece to remove material in a controlled and precise manner. The broach consists of a series of progressively larger cutting teeth, which gradually form the keyway or slot to the desired dimensions.

Step-by-Step Process

- Workpiece Preparation: The component is securely clamped to prevent movement.

- Broach Selection: The tool is chosen based on keyway dimensions, material type, and required tolerance.

- Cutting Operation: The broach moves through the workpiece, removing material in small increments.

- Finishing: Once the keyway is formed, the broach is removed, and the part may undergo minor finishing if required.

Keyway broaching is preferred over other methods like milling or slotting because it achieves high precision and consistent results with minimal finishing. Materials commonly machined include steel, stainless steel, aluminum, and specialized alloys.

Types of Keyway Broaching Machines

Choosing the right keyway broaching machine depends on the type of production, part size, and required precision.

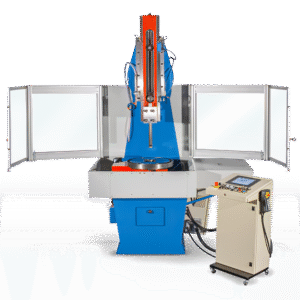

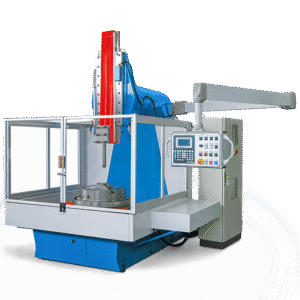

Horizontal vs Vertical Machines

- Horizontal Machines: Suitable for long shafts and high-volume production. They are robust and can handle heavy-duty operations.

- Vertical Machines: Compact design ideal for small parts or shops with limited floor space.

Manual vs CNC Machines

- Manual Machines: Cost-effective for low-volume production or small shops.

- CNC Machines: Offer higher precision, automation, and the ability to produce complex parts consistently.

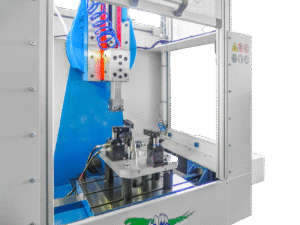

Specialized Machines for Small Parts

- Ideal for miniature shafts, gears, and medical or electronic components.

- Provide high precision for small, intricate keyways.

Hydraulic vs Mechanical Machines

- Hydraulic Machines: Smooth operation, high force, suitable for harder metals.

- Mechanical Machines: Faster operation, simpler maintenance, suitable for high-volume work with softer metals.

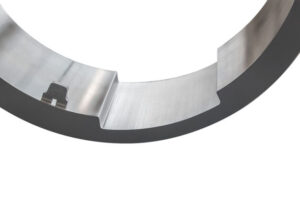

Components and Tooling

The broach tool is the most critical component of a keyway broaching machine. Its quality directly impacts precision and part consistency.

Types of Broach Tools

- Solid Broaches: Single-piece high-speed steel or carbide, used for standard operations.

- Modular Broaches: Adjustable teeth segments that can be replaced individually, reducing cost for long-term use.

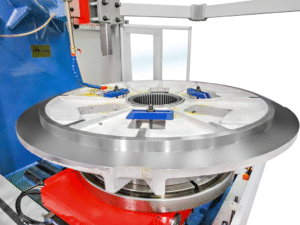

Accessories and Fixtures

- Guides and holders to maintain tool alignment

- Workpiece fixtures for stability during cutting

- Tool maintenance systems to extend tool life

Table: Key Tooling Materials and Uses

| Tool Material | Typical Use | Advantages |

| High-Speed Steel | Standard steel, mild alloys | Durable, cost-effective |

| Carbide | Hard metals, stainless steel | Longer tool life, high precision |

| Modular Segments | Custom or specialized parts | Replaceable teeth, cost saving |

Selecting the correct tooling depends on material hardness, keyway depth, and tolerances required for the part.

Applications of Keyway Broaching Machines

Keyway broaching machines are widely used across industries due to their ability to produce high-precision parts efficiently.

Automotive Industry

- Production of transmission shafts, gears, and pulleys

- Ensures consistency across high-volume production runs

Aerospace Industry

- High-precision components for engines and assemblies

- Materials: lightweight alloys, titanium, stainless steel

Industrial Machinery

- Components such as couplings, pulleys, and custom mechanical parts

- Small- to medium-batch production with tight tolerances

Medical and Electronics Components

- Small, intricate parts requiring miniature keyways

- High-precision machining critical for performance and reliability

Precision and Tolerances

Precision in keyway broaching depends on:

- Tooling quality and alignment

- Material properties and heat treatment

- Machine calibration and maintenance

Typical tolerances range from ±0.01 mm to ±0.05 mm, making keyway broaching ideal for demanding applications where accuracy is critical.

Choosing the Right Keyway Broaching Machine

When selecting a keyway broaching machine, consider:

- Production Volume: High-volume operations benefit from CNC or hydraulic machines.

- Part Size and Complexity: Small parts may require vertical or specialized machines.

- Material Type: Hard metals may need hydraulic machines with carbide tools.

- Budget vs Productivity: Balance initial investment with long-term efficiency.

For professional support on selecting the right machine, explore our broaching services.

Common Challenges and Solutions

Tool Wear and Breakage

- Regular inspections and using high-quality materials help minimize tool failure.

Material Deformation

- Proper clamping and controlled feed rates prevent warping or inaccurate cuts.

Small or Long Parts

- Specialized fixtures and machines designed for miniature or elongated components ensure precision.

Future Trends in Keyway Broaching Machines

- Integration with CNC automation and Industry 4.0 technologies for smarter operations

- Use of advanced tooling materials to extend tool life and reduce downtime

- Predictive maintenance systems to improve production efficiency and reduce errors

Conclusion

Keyway broaching machines are critical for producing high-precision components efficiently. Understanding the types, tooling, applications, and precision factors ensures manufacturers choose the right machine for their production needs.

For professional guidance on keyway broaching solutions or to discuss your manufacturing requirements, contact us today to learn more about our expertise.