Blind Hole Broaching for Precision Keyways & Splines

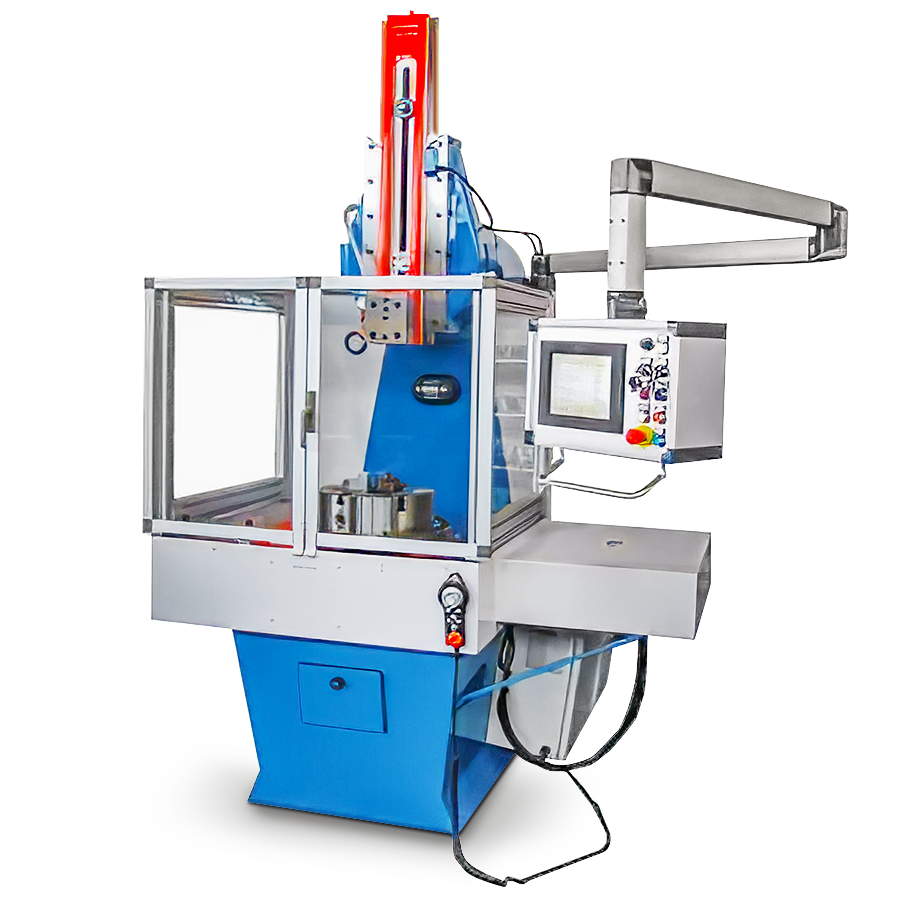

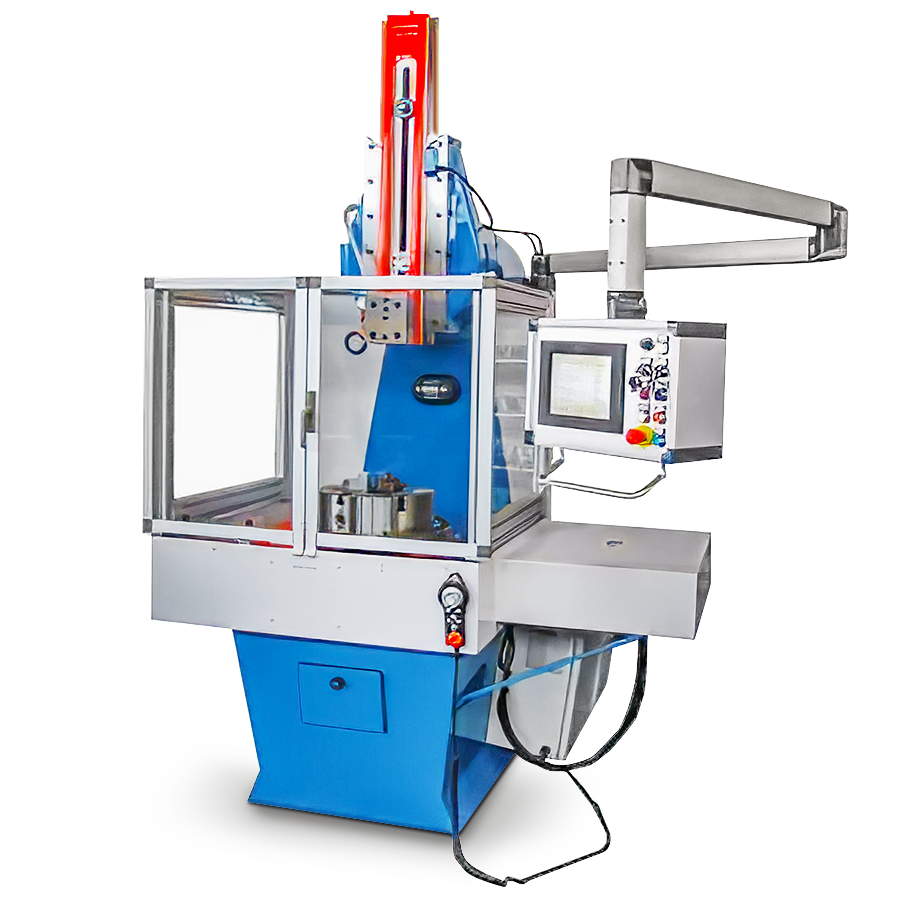

At Broaching Technologies, our blind hole broaching services are built around the unique vertical architecture and rigidity of CAMS slotting machines. This allows us to produce blind keyways and blind splines with exceptional accuracy, repeatability, and surface finish even in tight tolerance or challenging material applications.

Understanding Blind Hole Broaching

Blind hole broaching is the process of machining internal features such as keyways or splines that do not pass completely through a part. Because the broach cannot exit the workpiece, chip evacuation, tool relief, and depth control become significantly more complex than in standard broaching operations.

- Precise vertical control of the cutting stroke

- Specialized broach geometry

- Rigid fixturing and repeatable machine motion

Why Vertical Shapers and Keyseaters Make the Difference

Blind hole broaching is not well suited to traditional horizontal broaching systems. The vertical architecture of CAMS slotting machines provides critical advantages for blind applications

- Controlled vertical tool engagement

- Accurate depth stops for blind features

- Reduced chip packing through staged cutting

- Exceptional rigidity for tight tolerances

As the exclusive US distributor of CAMS slotting machines, Broaching Technologies operates the same precision equipment we supply to manufacturers, giving us unmatched insight into what these machines can achieve in real production environments.

Specialized in Blind Keyway and Blind Spline Broaching

While blind hole broaching can produce a variety of internal forms, our primary focus is on blind keyways and blind splines, two features critical to torque transmission and alignment in mechanical assemblies.

Blind Keyway Broaching

- Internal keyways that stop short of the part face

- Common in hubs, pulleys, gears, and couplings

- Maintains external part geometry while transmitting torque

Blind Spline Broaching

- Internal splines with precise tooth form and depth control

- Requires exceptional concentricity and profile accuracy

- Used in power transmission, automotive, and industrial machinery

Custom Tooling Designed for Blind Applications

Blind hole broaching success depends as much on tooling as it does on machine capability. Our team designs, maintains, and reconditions custom broach tools specifically engineered for blind operations.

- Chip relief geometry

- Progressive tooth loading

- Surface finish requirements

- Tool strength vs depth of cut

Materials We Commonly Broach

Our blind hole broaching services support a variety of materials commonly used in high performance components.

- Carbon and alloy steels

- Stainless steels

- Aluminum alloys

- Bronze and brass

- Inconel and other high strength alloys

We routinely achieve tight tolerances and repeatable surface finishes, even in challenging materials where blind features are traditionally difficult to machine.

Serving Precision Driven Industries

Our blind hole broaching services support manufacturers across multiple industries where precision internal features are critical.

Oil and Gas Equipment

Pump & Fluid Handling

Electric Motors & Power Transmission

Agricultural & Construction Equipment

Aerospace & Defense Components

Medical Device Manufacturing

Why Choose Broaching Technologies for Blind Hole Broaching?

Built for Precision Blind Hole Broaching

- Proven capability in blind internal features where tooling cannot exit the part

- Precise depth control for blind keyways and blind splines

- Specialized tooling designed to manage chip evacuation in blind applications

- Consistent geometry and surface finish in features that require exact stopping points

- Engineering expertise for complex part designs and tight depth tolerances

- Reliable results in materials that are traditionally difficult to blind broach

- Experience supporting both prototype and repeat blind broaching applications

Ready to Solve a Challenging Blind Broaching Application?

If your part design requires blind internal keyways or splines, Broaching Technologies offers a proven, precision driven solution backed by CAMS vertical slotting technology and decades of hands on experience.