Introduction

Contract broaching services are specialized manufacturing solutions where a company outsources broaching operations to a third-party provider rather than performing them in-house. These services are increasingly essential in modern manufacturing, allowing companies to access high-precision equipment and skilled operators without investing in costly machinery.

Outsourcing broaching operations offers numerous advantages, including cost savings, faster production cycles, and superior part quality. Manufacturers can scale production efficiently, meet tight deadlines, and reduce capital expenditure on broaching machines and tooling. By partnering with a reliable contract broaching provider, engineers and OEMs can focus on core operations while ensuring consistent, high-quality output.

For detailed specifications of broaching processes and tooling, visit Keyway & Spline Broaching Machines Overview.

This guide will provide a comprehensive overview of contract broaching services, their benefits, industries that leverage these services, selection criteria, and future trends in outsourced broaching.

What is Contract Broaching?

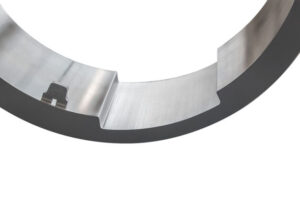

Contract broaching is a manufacturing service where companies hire external experts to perform broaching operations. Broaching involves using a linear tool with progressively larger teeth to cut precise keyways, slots, or internal profiles in a workpiece.

In-House vs Outsourced Broaching

- In-House Broaching: Requires investing in machines, tooling, and skilled operators. Suitable for companies with high-volume or continuous production needs.

- Contract Broaching: Outsourcing eliminates capital investment and allows access to advanced machines and expertise without long-term commitments.

Common Parts and Materials

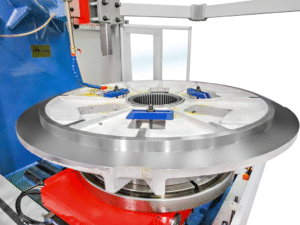

Contract broaching services typically handle:

- Parts: Shafts, gears, couplings, pulleys, and custom mechanical components

- Materials: Steel, stainless steel, aluminum, and specialized alloys

- Applications: Automotive components, aerospace parts, industrial machinery, and medical devices

Outsourcing broaching allows manufacturers to tackle specialized or high-precision components that may exceed the capabilities of in-house equipment.

Benefits of Contract Broaching Services

Outsourcing broaching provides multiple advantages to manufacturers and engineers.

1. Efficiency

- Faster production cycles due to pre-set broaching machines and experienced operators

- Avoid delays associated with machine setup or maintenance

- Ability to scale production for short-term or seasonal demands

2. Cost Savings

- Eliminates the need for capital-intensive equipment purchases

- Reduces tooling investment, especially for specialized or low-volume parts

- Minimizes overhead for machine maintenance and operator training

3. Access to Expertise

- Skilled operators with experience in precision broaching, custom tooling, and material handling

- Knowledgeable staff can recommend optimal broach designs and tolerances

- Reduces risk of errors and scrap due to operator inexperience

4. Quality and Consistency

- High-precision machines ensure tight tolerances and consistent parts

- Regular inspection and quality control measures reduce defects

- Ability to handle complex or miniature parts reliably

Contract broaching services allow companies to meet production deadlines, maintain high-quality standards, and reduce operational costs simultaneously.

Types of Contract Broaching Services Available

Different contract broaching providers offer various specialized services tailored to production needs.

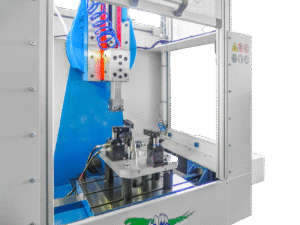

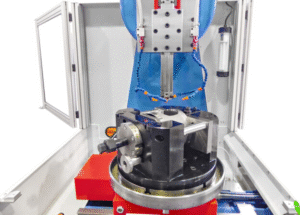

Precision Broaching Services

- Used for high-tolerance components requiring ±0.01 mm to ±0.05 mm accuracy

- Ideal for aerospace, automotive, and industrial machinery parts

Custom Broaching Services

- Tailored tooling and machine setups for unique or complex components

- Supports small production runs, prototype parts, and specialized internal keyways

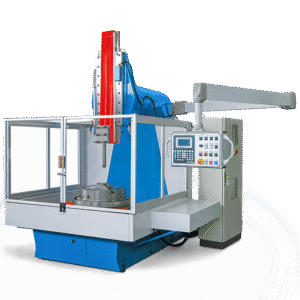

Large-Volume Production Broaching

- Capable of handling hundreds or thousands of parts per week

- Efficient workflow and automated broaching machines reduce cycle times

Small-Part and Internal Broaching

- Miniature components, medical devices, and electronic assemblies

- High-precision tooling ensures repeatability and accuracy for small geometries

By offering a range of services, contract broaching providers can accommodate various industries and production scales.

Industries That Benefit from Contract Broaching

Automotive

- Shafts, gears, and keyways for transmissions and drive components

- Contract broaching allows rapid scaling for high-volume production

Aerospace

- High-precision, safety-critical components for engines, turbines, and assemblies

- Ensures compliance with stringent tolerances and material standards

Industrial Machinery

- Pulleys, couplings, and custom mechanical parts

- Reduces in-house equipment requirements while maintaining part quality

Medical Devices

- Miniature components and surgical instruments

- High precision and repeatability are critical for performance and safety

Contract broaching enables companies in these sectors to achieve precision without investing heavily in machinery or skilled labor.

How to Select a Contract Broaching Partner

Choosing the right provider is essential for achieving consistent, high-quality output. Consider the following factors:

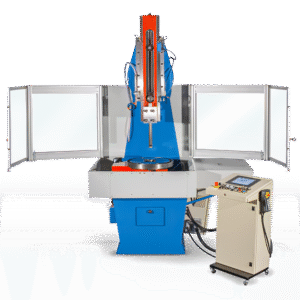

1. Experience and Reputation

- Suppliers with a proven track record in precision and custom broaching

- References and client testimonials demonstrate reliability

2. Capabilities and Machine Types

- Availability of CNC, horizontal, and vertical broaching machines

- Ability to handle specific materials and part geometries

3. Quality Certifications and Standards

- ISO 9001, AS9100, or other relevant industry certifications

- Demonstrates commitment to quality control and consistent output

4. Lead Times and Production Capacity

- Ensure the provider can meet your deadlines and scale production as required

- Evaluate their ability to handle urgent or high-volume orders

Selecting a partner with both technical expertise and operational reliability ensures smoother outsourcing and higher-quality results.

Common Challenges and How Contract Broaching Solves Them

Contract broaching can address several typical manufacturing challenges:

1. Equipment Maintenance and Downtime

- Outsourcing eliminates the need for in-house machine upkeep

- Reduces production downtime due to maintenance

2. Tooling Investment for Specialized Parts

- Providers already have advanced tooling for custom or high-precision components

- Eliminates large upfront tooling costs

3. Skilled Labor Shortages

- Access to experienced operators without hiring full-time staff

- Ensures precision even for complex or miniature components

By outsourcing, manufacturers can maintain efficiency and quality without significant capital investment.

Case Studies / Examples

Example 1: Automotive OEM

An automotive manufacturer outsourced high-volume gear broaching. Results:

- Reduced production cycle times by 25%

- Consistent tolerances for every gear shaft

- Lower capital expenditure on in-house machines

Example 2: Aerospace Supplier

A supplier achieved high-tolerance aerospace components using contract broaching:

- ±0.02 mm accuracy consistently maintained

- Reduced defects and scrap rates

- Faster turnaround for prototype and production parts

These examples highlight how contract broaching improves efficiency, quality, and cost-effectiveness.

Future Trends in Contract Broaching

- CNC Automation: Smart machines improve precision and reduce operator dependency

- Advanced Tooling: Longer-life broaches reduce replacement costs

- Global Outsourcing: Manufacturers increasingly partner with specialized broaching providers worldwide for efficiency and access to advanced equipment

Staying aware of these trends helps manufacturers leverage the latest technology for competitive advantage.

Conclusion

Contract broaching services provide manufacturers with efficiency, cost savings, and high-quality output. By outsourcing precision or custom broaching, companies can access advanced equipment, skilled operators, and flexible production capacity without significant capital investment.

For companies looking to optimize production and maintain high precision, partnering with an experienced contract broaching provider is a strategic solution. For more information or to discuss your broaching requirements, contact experts specializing in precision and custom broaching solutions via Keyway & Spline Broaching Machines.