CAMS Slotting Machines: Boost Throughput with 1500-Axis Indexing

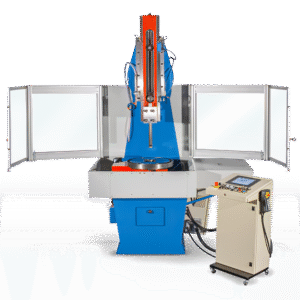

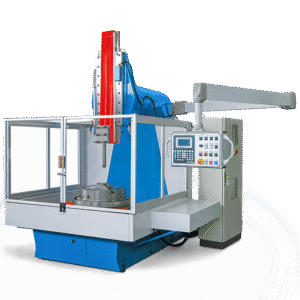

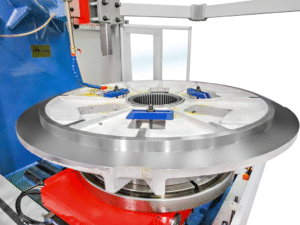

In today’s competitive manufacturing environment, efficiency and precision are no longer optional — they are essential. Production planners are constantly challenged to deliver consistent quality at higher volumes, often under tight deadlines. One technology helping manufacturers meet these demands is the CAMS slotting machine. With features such as NC axis control and 1500-axis indexing, these machines offer reliability, accuracy, and significant return on investment.

This blog explores the benefits of CAMS slotting machines, their role in slotted groove production, how they compare to broaching, and why production planners should consider them as part of their long-term strategy.

What Are CAMS Slotting Machines?

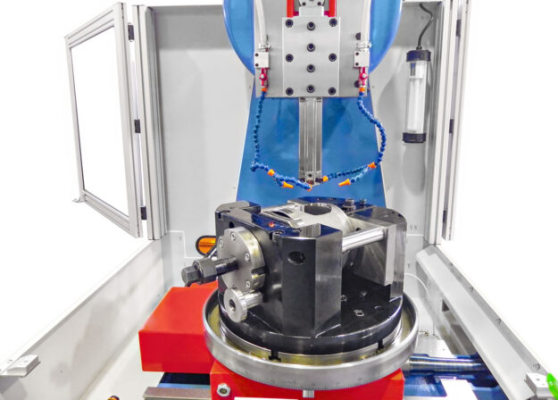

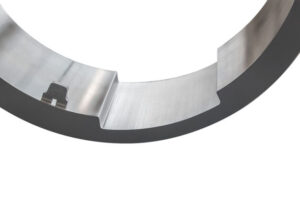

Slotting machines are specialized tools designed to create grooves, slots, and keyways in metal components. They are essential for industries such as automotive, aerospace, and heavy engineering, where precision machining directly affects product performance.

CAMS slotting machines stand out because they are engineered with advanced controls, including NC axis technology and 1500-axis indexing. These features allow manufacturers to reduce setup times, cut production costs, and ensure repeatable accuracy across large batches.

CAMS Slotting Machines Benefits

1. Precision in Every Cut

One of the most significant CAMS slotting machines benefits is the precision they deliver. With NC axis control, each slot is produced to exact dimensions, ensuring uniformity and reducing errors that might lead to costly rework.

2. Higher Throughput with 1500-Axis Indexing

The 1500-axis indexing allows rapid repositioning of parts during production. This reduces downtime between cuts and accelerates cycle times, leading to higher overall throughput. For production planners, this means schedules can be met without compromising quality.

3. Versatility Across Applications

From cutting keyways in shafts to producing splines and grooves in complex components, CAMS slotting machines are versatile. Their ability to handle a wide range of part geometries makes them a practical choice for industries with diverse machining requirements.

4. Reduced Tooling Costs

Unlike broaching, which often requires expensive, custom-designed tools, slotting machines typically use more affordable cutters that can be reused and reconditioned. This makes them a cost-effective solution for manufacturers managing multiple part designs.

5. Long-Term ROI

While CAMS slotting machines may require a higher initial investment than conventional systems, the combination of precision, speed, and reduced downtime ensures better returns over time. Manufacturers benefit from increased output and lower scrap rates, which directly improve profitability.

Slotting vs Broaching: A Comparison

When evaluating machining methods, production planners often compare slotting vs broaching. Both processes have their merits, but slotting with CAMS technology offers several unique advantages.

| Feature | Slotting (CAMS Machines) | Broaching |

| Flexibility | Handles multiple slot types and dimensions with program adjustments | Limited to fixed shapes defined by broach |

| Tooling Costs | Lower; cutters can be reused and reconditioned | Higher; custom broaches are costly |

| Precision | High accuracy with NC axis control | Good precision but less adaptable |

| Setup Time | Minimal, thanks to 1500-axis indexing | Longer, as broaches require more complex setup |

| Best Use Case | Mixed production, evolving designs, medium to high volumes | Very high volume, stable part designs |

This comparison shows that while broaching may suit very high-volume, stable production environments, CAMS slotting machines are more flexible, cost-effective, and adaptable for varied production needs.

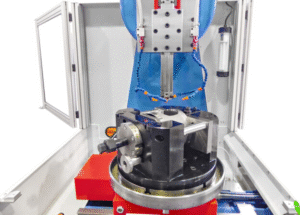

The Role of NC Axis in Slotting Machines

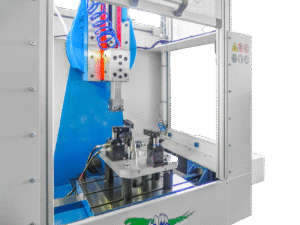

The slotting machine NC axis is a game-changer in modern machining. It allows digital control of stroke length, feed rate, and depth, offering several key advantages:

- Consistency – Every slot is cut to the same specification, reducing variation.

- Efficiency – Automated adjustments shorten setup and changeover times.

- Traceability – Digital programs can be stored and recalled, ensuring repeatable production across batches.

- Error Reduction – With less manual intervention, the chances of human error are significantly reduced.

For production planners, NC axis control translates to predictable cycle times and greater scheduling accuracy.

Applications of Slotted Groove Production

Slotted grooves are used in a wide range of industrial applications. Some common uses include:

- Automotive Components – Keyways in shafts, gears, and couplings.

- Aerospace Parts – Precision grooves in critical components where safety and performance are vital.

- Heavy Machinery – Splines and load-bearing slots in durable parts.

- Tooling and Dies – Grooves required for molds and precision tools.

By supporting such a wide variety of applications, CAMS slotting machines ensure that manufacturers can meet diverse industry demands with a single investment.

Why Work with a CAMS Dealer?

Choosing the right machine is only the first step. Working with a certified CAMS dealer ensures that manufacturers have access to:

- The latest machine models and configurations

- Expert guidance on selecting the right machine for specific needs

- Ongoing technical support and training

- Access to spare parts and specialized slotting cutters

ROI Considerations for Production Planners

Investing in advanced slotting machines requires a careful look at return on investment. Here are some of the main factors to consider:

- Increased Productivity – Faster cycle times and reduced downtime improve output.

- Reduced Scrap – High precision lowers the risk of defective parts.

- Lower Tooling Costs – Reusable cutters minimize recurring expenses.

- Operational Efficiency – Shorter changeovers allow for smoother scheduling.

When analyzed over time, these benefits often outweigh the initial investment, making CAMS slotting machines a strategic choice for long-term production planning.

Conclusion

For production planners seeking reliable, adaptable, and cost-effective machining solutions, CAMS slotting machines provide clear advantages. With advanced features like NC axis control and 1500-axis indexing, they deliver precision, higher throughput, and long-term ROI. Compared with traditional broaching, slotting offers greater flexibility and lower tooling costs, making it a valuable investment for manufacturers across industries.

By partnering with a trusted CAMS dealer and carefully evaluating production needs, businesses can ensure they select the right machine to meet current demands while preparing for future growth.

The key benefits include high precision, faster throughput with 1500-axis indexing, lower tooling costs, and better flexibility for mixed production.

Slotting is generally more flexible and cost-effective, while broaching is suited for very high-volume, stable designs. For most manufacturers with varied production, slotting is the more practical option.

The NC axis provides programmable control over stroke, feed, and depth, ensuring consistent quality and reducing manual setup time.

Industries such as automotive, aerospace, heavy machinery, and tooling benefit from precise slotted groove production.

The best way is through an authorized CAMS dealer, where you can review available machines and receive tailored advice. Visit the official contact page for more details.