Why Spline Accuracy Impacts Mechanical Assembly

In high-performance mechanical systems, long splines ensure both torque transmission and part alignment over extended lengths. When not machined precisely, long splines can cause misfits, increased wear, and mechanical failure. High precision in long-spline broaching ensures correct mating, zero runout, and maximum product reliability—especially for OEM components used in aerospace, automotive, and industrial machinery.

The Challenge of Long-Spline Geometry

The longer the spline, the greater the chance for error. Tool deflection, uneven wear, material inconsistencies, or fixture misalignment are amplified over longer spline distances. Precision becomes exponentially more important as length-to-diameter ratios increase, making long-spline broaching a specialty process requiring strict control.

What is Long-Spline Broaching?

Definition and Applications

Long-spline broaching refers to the process of machining deep or extended spline profiles (typically internal) using specialized broach tools and machines. These splines often exceed three inches in length and appear in applications requiring high torque transfer and axial stability.

Examples include:

- Transmission and axle shafts

- Aerospace engine shafts and couplings

- Gearbox splines in industrial systems

- Hydraulic system shafts

Long splines are especially important when the mechanical assembly must distribute torque along a greater surface area or achieve higher levels of part alignment in critical systems.

Why Length Magnifies Tolerance Issues

With standard splines, minor tool drift or misalignment might go unnoticed. In long splines, these imperfections accumulate, leading to:

- Tapered profiles or bell-mouth effects

- Tooth pitch variation

- Decreased strength and spline wear

- Increased vibration and system noise

Achieving uniformity throughout the entire spline length is essential for long-term performance, particularly in mission-critical applications.

Factors That Affect Spline Broaching Accuracy

Broach Tool Design and Wear

Long broaches must maintain dimensional consistency throughout the stroke. Any variation in tooth height or wear along the broach causes profile distortion. Progressive tooth cutting and proper rake angle design are critical in managing cutting forces.

Best practices:

- Use hardened broach tools with precision-ground teeth

- Monitor tool wear and apply scheduled regrinding

- Choose coated tools (TiN, TiAlN) for harder materials

- Utilize software modeling to simulate broach/tool performance before production

Material Type and Hardness

Material machinability greatly influences broaching accuracy. Hard or tough alloys cause higher tool wear, while softer materials may deform or gall. The ideal material will have good chip control and minimal work hardening.

Recommendations:

- Use annealed stock where possible

- Match broach tooth angles and coatings to material

- Ensure consistency in raw material batches

- Consider pre-machining operations like drilling or rough milling to reduce broach load

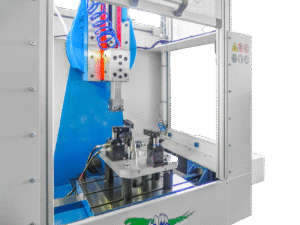

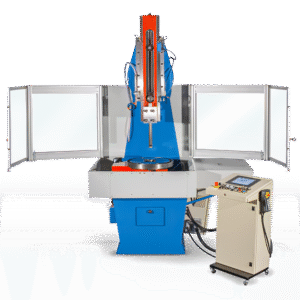

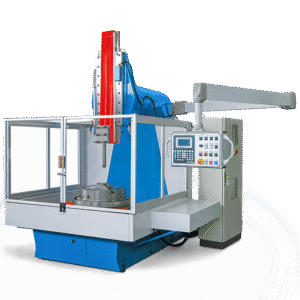

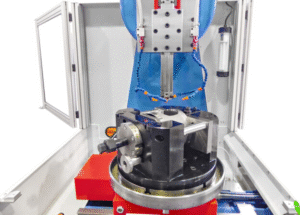

Machine Calibration and Stability

Long broaching strokes demand rigid, well-aligned machines. Any looseness or backlash leads to cumulative errors. Vibration during the cut may cause uneven tooth forms or chatter marks, affecting both fit and aesthetics.

Tips:

- Calibrate machines regularly and check for thermal expansion effects

- Use machines designed for deep broaching

- Stabilize the workpiece with minimal vibration

- Implement dynamic dampening systems or linear rails for smooth broach movement

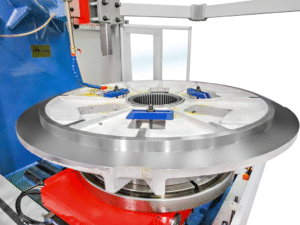

Fixturing and Part Holding Techniques

Proper fixturing is crucial to prevent deflection, misalignment, or slippage. Poor fixturing introduces twist and taper into the final cut.

Fixtures should:

- Support the entire part length with even clamping force

- Use hardened reference points and adjustable rests

- Prevent rotational or axial movement during cutting

- Be verified for repeatability using trial runs and control samples

Managing Spline Length and Tolerances

Strategies to Maintain Tooth Alignment

Keeping spline teeth aligned over extended lengths ensures proper fit and performance. Misaligned teeth can cause part interference and lead to premature wear.

Solutions include:

- Using pilot guides or bushings to reduce broach wander

- Sequencing broach tooth profiles progressively to reduce force concentration

- Controlling stroke speed and force with CNC broach control systems

- Using real-time monitoring tools to detect tool deflection

Avoiding Taper and Twist in Long Cuts

Taper occurs when broach entry and exit diameters differ. Twist results from uneven cutting pressure or misaligned tooling. Both impact spline engagement quality.

Prevention:

- Use pull broaching where possible for consistent axial force

- Maintain broach sharpness and geometry

- Stabilize cutting force throughout the stroke with pre-set pressure curves

- Implement intermediate inspection checkpoints

Role of Pull Broaching vs. Push Broaching

- Pull broaching: Ideal for deep internal splines; offers better alignment and force control with guided movement

- Push broaching: Shorter strokes; better suited to shorter or external splines; susceptible to tool deflection over longer paths

For long splines, pull broaching is generally superior due to reduced deflection risk and improved control throughout the stroke.

Inspection Methods for Long-Spline Broaches

CMM Validation

Coordinate Measuring Machines (CMMs) offer detailed verification of spline tooth spacing, pitch diameter, and length accuracy. These machines can also record inspection data for traceability and quality assurance.

- Use for first-article inspection, batch sampling, and tool wear tracking

- Helps validate form, profile, and concentricity

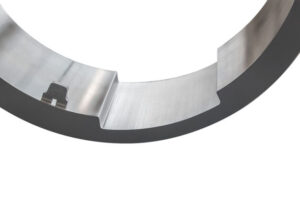

Go/No-Go Gauging

Custom plug or ring gauges are efficient for checking production parts quickly. They verify that spline dimensions fall within tolerance, though without detailed metrics.

- Design gauges to fit entire spline length

- Combine with functional testing where applicable

Visual and Surface Finish Inspections

Surface irregularities, tool marks, and finish inconsistencies can affect spline engagement, cause excessive wear, or introduce vibration in assembly.

Ideal surface finish: 16–32 µin Ra for most long spline components

- Inspect for burrs, scratches, tool chatter, and residue

- Use borescopes for internal splines when necessary

Best Practices for OEM-Grade Long-Spline Components

Controlling Tool Deflection

Minimizing tool deflection is key for spline straightness and uniform tooth profile. Tool deflection causes angular misalignment and loss of concentricity.

Approaches include:

- Using shorter, stiffer broach setups or segmented tooling

- Reducing unsupported tool length with piloting sleeves

- Balancing feed rate and cutting force to prevent stress build-up

- Ensuring broach lubrication to reduce friction and heat buildup

Material Conditioning (Annealing or Hardening)

Broaching can be performed pre- or post-heat treatment depending on application. Softening the material allows for cleaner cuts, while post-broach heat treating enhances hardness and wear resistance.

- Annealing before broaching: Improves machinability and tool life

- Case hardening after broaching: Increases surface hardness without affecting spline geometry

- Nitriding or carburizing: Common for wear-critical automotive and aerospace parts

Repeatability Across Production Batches

High-precision production requires tight process control, especially for OEMs that demand part traceability, long service life, and zero-defect quality.

Consistency depends on:

- Standardized tooling maintenance and change intervals

- Batch inspection procedures with SPC (Statistical Process Control)

- Documented fixturing and machine parameters

- Digitally logged inspection and quality data for audits

Conclusion

Recap of Accuracy Factors

Achieving precision in long-spline broaching requires rigorous control over all elements—from broach design to fixturing and inspection. Long spline machining is not just an extension of standard broaching but a specialized process that demands precise control, dedicated machines, and expert knowledge.

Whether for an aerospace turbine or an electric vehicle drivetrain, long-spline precision is key to system performance, durability, and safety.

Request a Long-Spline Broaching Consultation

Looking to improve your long-spline broaching accuracy? Contact our engineering team to review your specs, tolerances, and production goals. We specialize in internal and external broaching for complex, extended spline profiles. Let us help you deliver OEM-quality results on every part.