Keyway Broaching Services for Precision Internal Slots

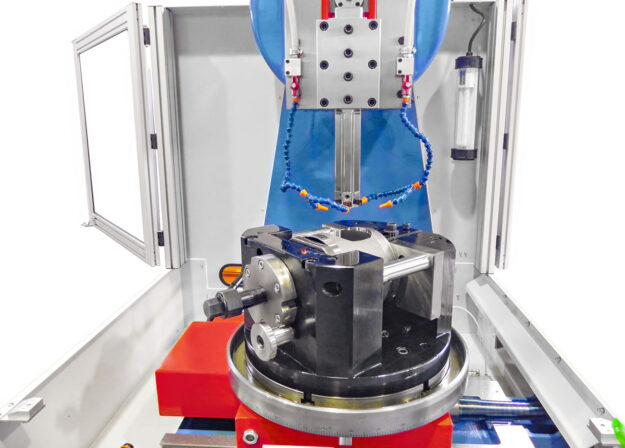

At Broaching Technologies, our keyway broaching services are performed using rigid vertical slotting machines that provide precise stroke control and consistent cutting action. This approach allows us to produce accurate internal keyways with reliable depth, width, and surface finish across both prototype and production volumes.

What Is Keyway Broaching?

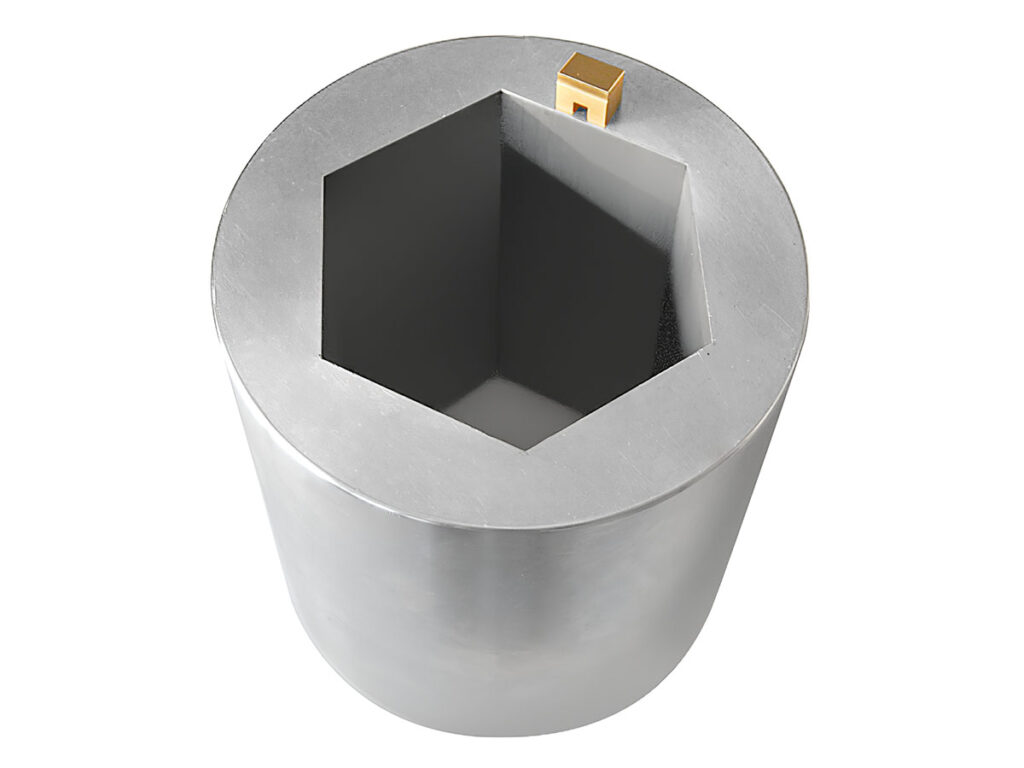

Keyway broaching is the process of machining a single internal slot within a bore to accept a mating key. This slot allows torque to be transferred from a shaft to a hub while maintaining proper alignment between components.

- Machines a single internal slot within a bore

- Allows torque transfer between shaft and hub

- Maintains alignment between mating components

- Commonly used in gears, pulleys, hubs, and couplings

Why Keyway Broaching Requires Precision Equipment

Keyway broaching requires accurate control of slot width, depth, and straightness to ensure proper fit and load transfer. Variations in geometry can lead to poor alignment, uneven load distribution, or premature wear.

- Precise stroke control ensures consistent keyway depth

- Rigid machine structure minimizes tool deflection

- Controlled cutting motion improves slot accuracy

- Repeatable results across production volumes

As the exclusive US distributor of CAMS slotting machines, Broaching Technologies operates the same precision equipment we supply to manufacturers, giving us unmatched insight into what these machines can achieve in real production environments.

Keyway Broaching as a Core Capability

Keyway broaching is a core capability at Broaching Technologies, supporting manufacturers that require dependable internal keyways for power transmission and mechanical assemblies.

Sunk Key Broaching

Saddle Key Broaching

Tangent Key Machining

Round Keyway Cutting

Spline Keyway Broaching

Keyseat Machining

Tooling and Engineering Expertise for Keyway Broaching

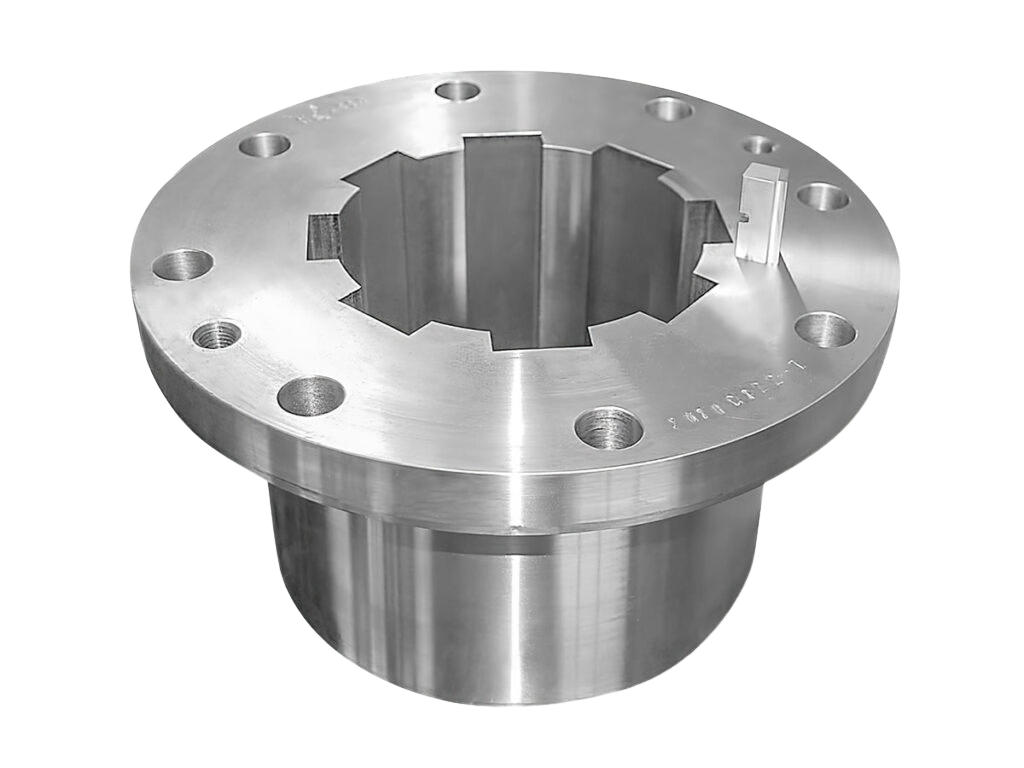

Keyway broaching performance depends heavily on tooling design and condition. Broaching Technologies designs, maintains, and reconditions custom broach tools to match specific keyway sizes, materials, and tolerance requirements.

- Custom broach tooling designed for specific keyway dimensions

- Progressive cutting geometry for controlled material removal

- Tool maintenance and reconditioning for consistent performance

- Engineering review of part geometry and tolerances

Materials We Commonly Broach

Our keyway broaching services support a wide range of materials commonly used in mechanical and power transmission components.

- Carbon and alloy steels

- Stainless steels

- Aluminum alloys

- Bronze and brass

- Inconel and other high strength alloys

With controlled cutting strategies and rigid machine platforms, we achieve tight tolerances and repeatable surface finishes across these materials.

Industries That Rely on Keyway Broaching

Our keyway broaching services support manufacturers across a wide range of industries where reliable torque transmission and component alignment are essential.

Oil and Gas Equipment

Pump & Fluid Handling

Electric Motors & Power Transmission

Agricultural & Construction Equipment

Aerospace & Defense Components

Medical Device Manufacturing

Why Choose Broaching Technologies for Keyway Broaching?

Specialists in Accurate Internal Keyway Broaching

- Accurate internal keyways with consistent width, depth, and straightness

- Vertical slotting machines provide precise stroke control for clean keyway geometry

- Custom keyway tooling matched to part size and tolerance requirements

- Proven capability across gears, pulleys, hubs, and couplings

- Reliable results for prototype and repeat production work

- Tight fits that support proper load transfer and long service life

- Engineering review to ensure manufacturability and performance

Ready to Get Started with Keyway Broaching?

If your application requires accurate internal keyways with proper fit and dependable torque transfer, Broaching Technologies delivers precision keyway broaching backed by controlled machining and proven process expertise.