Slotting machines play a critical role in precision machining, particularly for grooves, keyways, and splines in gears, shafts, and other mechanical components. Choosing the right slotting machine is essential to achieve accurate dimensions, maintain tight tolerances, and optimize production efficiency. Manufacturers, production engineers, and shop managers must consider not only the machine specifications but also their specific material and tolerance requirements, the type of workpieces they handle, and the supplier’s expertise.

For more information on our services, visit Broaching Technologies to see how our expertise in slotting and broaching can support your production requirements.

Slotting Machine vs. Broaching Machine – Understanding the Difference

While slotting and broaching are both used to create internal shapes in metal components, the processes are fundamentally different in operation and application.

- Slotting Machines: These machines operate with a vertical reciprocating motion, using a single-point cutting tool to remove material incrementally. Slotting is ideal for creating grooves, splines, or internal keyways, particularly in low-to-medium volume production or custom workpieces where precision and flexibility are required.

- Broaching Machines: Broaching uses a toothed tool that passes through the workpiece in a single stroke or series of strokes, making it ideal for high-volume production where consistency and tight tolerances are critical. Broaching is highly efficient but less flexible when frequent design changes or custom profiles are needed.

When to Use Slotting vs. Broaching

Slotting is preferable when:

- You require custom profiles or variable groove sizes.

- Production volumes are moderate and tooling changes are frequent.

- You need high precision but with flexibility for adjustments.

Broaching is preferable when:

- You are manufacturing high volumes with consistent parts.

- Tight tolerances are non-negotiable.

- The design requires repetitive internal features, such as splines and keyways, across multiple parts.

Understanding the difference is essential to ensure the investment in a slotting machine or broaching system meets your production goals and maintains quality standards.

Key Features to Evaluate When Buying a Slotting Machine

Not all slotting machines are created equal. Evaluating the right features ensures that the equipment can handle your production needs and deliver consistent, high-quality results.

Number of NC Axes (1–4)

Modern slotting machines can feature 1 to 4 NC-controlled axes, enabling more complex machining capabilities. Multiple axes allow precise tool movement, angular positioning, and indexing, which is critical for machining splines and grooves with high accuracy. NC-controlled machines reduce setup errors, increase repeatability, and provide greater control over tool paths. For complex workpieces, multi-axis machines are almost indispensable.

Electronic Tool Lift and Feed Mechanisms

Electronic tool lift and feed mechanisms control the vertical motion of the cutting tool, providing consistent feed rates and stroke precision. These systems minimize vibration, reduce tool wear, and improve surface finish, which is particularly important for hardened steels and other difficult-to-machine materials. This level of control ensures that groove dimensions, depths, and spacing are consistently accurate.

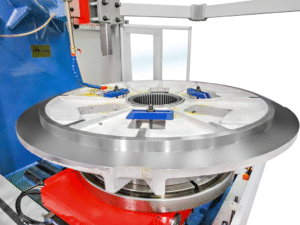

Turntable Capacity and Divisions

Precision turntables are crucial for indexing operations. Machines with high turntable division capacity allow for precise spacing of splines or keyways, reducing the need for secondary adjustments. High-capacity turntables, sometimes with up to 1500 divisions, ensure uniform angular spacing, which is essential for applications in automotive, aerospace, and industrial machinery components.

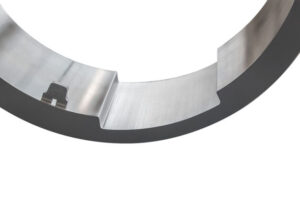

Understanding Groove and Spline Machining Requirements

The nature of the workpiece has a significant impact on the machine features you need. Factors like material type, tolerance requirements, and complexity of the profile determine the machine’s suitability.

Material Considerations

Slotting machines must handle a wide variety of materials, including:

- Stainless Steel: Requires rigid construction and stable feed mechanisms to avoid deflection and tool wear.

- Brass and Aluminum: Softer materials may need specialized tooling to prevent surface damage or tearing.

- Hardened Alloys and Special Metals: Demands higher spindle power and durable tooling to maintain accuracy.

Ensuring that the machine can handle your production materials without sacrificing precision is critical.

Tolerances and Precision

Machining internal grooves, splines, and keyways often requires tolerances within ±0.01 mm or tighter. Selecting a machine with precise feed controls, accurate tool positioning, and high-quality spindle construction ensures that finished parts meet specification consistently. Precision machining reduces scrap, improves assembly fit, and enhances overall product reliability.

Evaluating Suppliers: New vs. Used Machines

Choosing the right supplier is as important as choosing the machine itself. Factors to consider include the condition of the machine, service availability, and the expertise of the supplier.

- New Machines: Offer the latest technology, improved reliability, and warranty coverage. They also often include NC controls, automation options, and higher precision components.

- Used Machines: Can be a cost-effective solution if carefully inspected and refurbished. It’s important to verify spindle integrity, tool alignment, and feed mechanism condition.

- Authorized Dealers: Offer assurance, installation support, and after-sales service. Working with a reputable dealer ensures that your investment in machinery is protected and that any technical issues are addressed promptly.

At Broaching Technologies, we guide our customers in selecting machines that fit their specific applications and provide support throughout the lifecycle of the equipment. You can explore our Slotting Machines Services for detailed offerings.

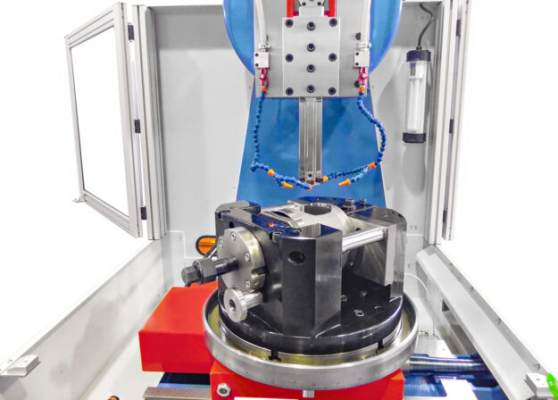

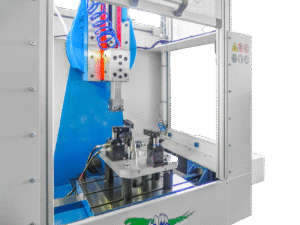

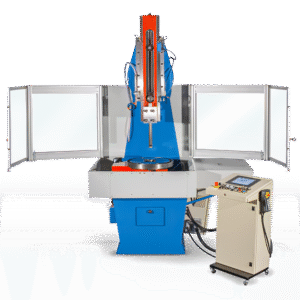

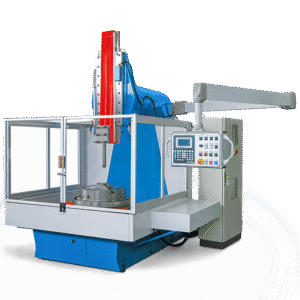

Why the C.A.M.S. Series Is a Preferred Choice

The C.A.M.S. series of slotting machines is well-known for reliability, precision, and versatility in groove and spline machining.

Models 200–850 Overview

These models feature:

- Stroke lengths from 200 mm to 850 mm, suitable for small to large components.

- Adjustable speeds and feeds, allowing optimization for different materials.

- NC axis options, providing flexibility for complex profiles.

- Heavy-duty construction, ensuring stability and vibration resistance even during extended operation.

The C.A.M.S. series is particularly effective for applications in automotive, aerospace, and industrial machinery where consistency and precision are essential.

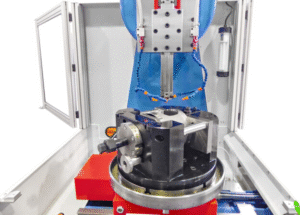

Case Study: Real-World Slotting Machine Application

A precision components manufacturer faced difficulty producing deep internal splines in hardened steel shafts. Traditional broaching methods caused tool deflection and inconsistent tolerances.

After investing in a C.A.M.S. 600 slotting machine, they achieved:

- ±0.01 mm repeatability across all splines

- Reduced setup time by 35%

- Improved surface finish, eliminating secondary operations

This example demonstrates how selecting the right machine with the correct features can optimize productivity, maintain part quality, and reduce overall manufacturing costs.

Summary: Making the Right Investment in Slotting Machines

Selecting the right slotting machine for grooves and splines requires:

- Understanding the difference between slotting and broaching processes.

- Evaluating key machine features like NC axes, feed mechanisms, and turntable capacity.

- Considering the materials you will machine and the tolerances required.

- Choosing a reliable supplier for new or refurbished equipment with technical support.

- Assessing specialized machine series, such as C.A.M.S., for specific production needs.

At Broaching Technologies, we assist manufacturers in selecting the most suitable machinery for their operations. Our expertise in slotting and broaching allows us to provide solutions that meet high-precision requirements efficiently. For further assistance, visit our Slotting Machines Services page or contact us directly through our Contact Us page to discuss your specific requirements.