In precision manufacturing, outsourcing broaching services is often a smart decision especially when internal capabilities don’t justify the cost of dedicated broaching machines or tooling. At Broaching Technologies, we understand that choosing the right partner can be the difference between consistent, high-quality parts and costly production setbacks.

However, manufacturers frequently make critical errors when outsourcing these specialized services. These mistakes can lead to tolerance failures, rework, extended lead times, or even damaged components.

This guide highlights five common mistakes to avoid when outsourcing broaching work, helping you make an informed decision that safeguards your productivity and part quality.

Mistake 1: Selecting Based Solely on Lowest Price

When choosing a contract broaching provider, it’s tempting to prioritize cost over capability. However, price alone rarely reflects the true value of a service in precision machining.

Why Quality and Tooling Matter More Than Cost

A low quote might look appealing upfront, but if the vendor uses worn-out broaches, outdated fixtures, or uncalibrated machines, the resulting inaccuracies can quickly negate any savings.

Precision keyway and spline broaching requires reliable tools, calibrated machines, and skilled operators. Even minor tool wear or vibration can cause taper errors or surface inconsistencies that render parts unusable.

Consider this example:

A supplier quoting 20% lower than average may not include tool re-sharpening, inspection, or quality reporting all essential for consistent accuracy. Over time, these missing quality steps can lead to expensive part rejections and schedule delays.

When evaluating vendors, always weigh total value over initial cost. The best choice balances price with proven technical capability, repeatability, and customer support.

Mistake 2: Not Verifying Equipment & Tooling Capability

Another common oversight is assuming that all broaching vendors offer the same range of capabilities.

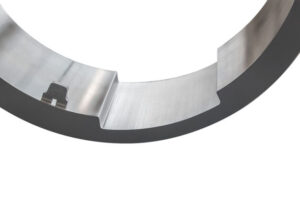

Does the Vendor Handle Blind Keyways, Splines, Long Keyways?

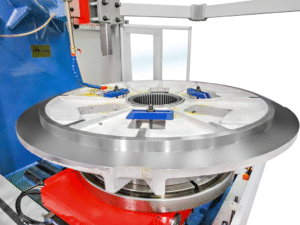

Every component has unique dimensional and material challenges. If your project requires blind keyways, extra-long internal slots, or involute splines, ensure your chosen provider has both the right equipment and tooling inventory to meet those specifications.

For instance:

A vendor equipped only for short, through-broach operations may struggle to achieve depth consistency in blind-hole keyways or may lack fixtures for long spline alignment.

When vetting suppliers, ask about:

- Stroke length and maximum part diameter

- Availability of form, involute, or serration broaches

- Fixturing setups for custom geometries

- Machine age, calibration, and maintenance frequency

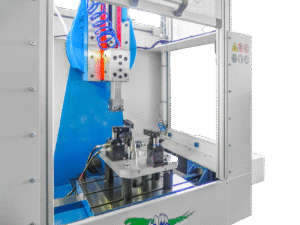

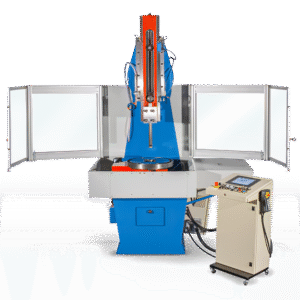

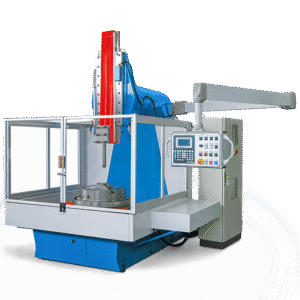

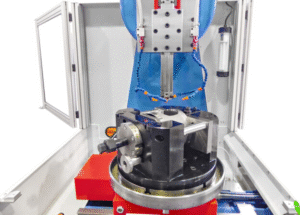

Broaching Technologies maintains a full range of precision keyway and spline broaching machines, allowing us to handle complex profiles and materials efficiently. For more detail on our services, visit the Broaching Services page.

Mistake 3: Lack of Process Transparency & Quality Control

Transparency is the foundation of any successful outsourcing partnership. Without it, there’s no assurance of how parts are being machined, inspected, or validated.

Inspection Protocols, Grinding Technology, Tolerance Tracking

A reliable broaching partner should have documented inspection procedures and a defined quality assurance process. These ensure that every part meets drawing specifications before shipment.

Ask about:

- Tool reconditioning and resharpening cycles

- In-process inspection checkpoints

- Post-broach grinding or honing operations for precision surfaces

- Tolerance tracking and digital reporting

A vendor unwilling to share process details may be hiding inconsistencies or skipping key quality steps.

Example: Broaching Technologies’ Process for Keyway Broaching

At Broaching Technologies, each job begins with engineering review and tooling verification. During production, operators perform continuous inspection, verifying dimensions using calibrated gauges and coordinate measuring tools. Post-machining, every component undergoes final inspection before delivery.

This disciplined process minimizes variation and ensures each batch meets customer specifications from prototype runs to full-scale production.

Mistake 4: Ignoring Material Challenges

Broaching performance varies greatly depending on material type. Ignoring these differences can lead to tool breakage, poor surface finish, or non-conforming parts.

Why Stainless, Brass, and Special Alloys Demand More from Broaching Services

Materials such as stainless steel, nickel alloys, or brass exhibit unique cutting behaviors. Stainless tends to work-harden, requiring sharper tools and optimized feeds, while brass demands fine control to prevent chatter or burr formation.

A vendor experienced only with standard carbon steels may lack the expertise or tooling geometry required for specialty alloys.

| Material Type | Machining Challenge | Required Approach |

| Stainless Steel (300/400 series) | High work-hardening tendency | Sharp broaches, lower feed rates, coolant optimization |

| Brass & Bronze | Chatter and burr formation | Fine-tuned tool rake angles and finishing passes |

| Alloy Steels (4140, 4340) | High cutting resistance | Coated broaches, controlled chip removal |

| Aluminum | Material build-up on cutting edges | Polished tools and coolant flow control |

Before awarding a project, confirm whether the vendor has prior experience with your material type and can demonstrate consistent surface finish results.

(For an in-depth discussion, refer to our upcoming blog on Material Challenges in Broaching.)

Mistake 5: Poor Communication and Project Management

Even with technical expertise, poor communication can derail a broaching project. Clear updates, responsive collaboration, and realistic scheduling are essential to keeping production on track.

Lead Times, Design Changes, Tooling Set-Up Flexibility

Delays often occur when part drawings are revised mid-project or when tooling adjustments are needed. A professional broaching partner anticipates these situations with flexible tooling setups and open communication channels.

Evaluate your supplier’s responsiveness to:

- Lead time estimates and capacity updates

- Drawing revisions or design clarifications

- Project milestone reporting

- Tooling changeovers or alternate fixture setups

An organized, communicative vendor ensures both consistency and accountability from prototype through production.

How to Make the Right Decision – Key Questions to Ask Your Broaching Partner

Selecting a reliable broaching provider requires understanding their processes, capabilities, and quality commitment. Use the following questions as part of your evaluation checklist:

- What materials do you handle?

Can they broach both soft and hard metals without compromising tolerance? - What shapes or profiles can you produce?

Ask about experience with involute splines, serrations, hexes, and custom keyways. - What dimensional tolerances can you achieve?

Ensure they can maintain consistent precision within your required range. - What inspection equipment do you use?

Confirm the use of calibrated gauges, micrometers, and digital inspection reports. - What is your typical lead time for prototype and production runs?

A realistic schedule helps prevent unexpected bottlenecks in your supply chain.

By asking these targeted questions, you gain a clearer understanding of whether a potential partner aligns with your technical and operational goals.

Conclusion: Partner with Proven Broaching Experts

Outsourcing broaching services can streamline production, reduce costs, and ensure exceptional precision — but only if the right partner is chosen. Avoiding these five common mistakes ensures your components meet exact specifications, on schedule, and within budget.

At Broaching Technologies, we provide dependable keyway, spline, and internal broaching services backed by decades of experience and rigorous quality control. Our team combines advanced machinery, skilled technicians, and transparent communication to support manufacturers across North America.

To discuss your project or request a quote, contact us today.