When it comes to precision component manufacturing, keyway and spline broaching play a vital role in achieving accurate, repeatable internal profiles. At Broaching Technologies, we specialize in contract broaching services in Milwaukee, offering manufacturers the expertise and technology needed to produce high-tolerance parts with efficiency and reliability.

Broaching is a machining process that removes material with a toothed tool called a broach. It’s commonly used to create internal or external keyways, splines, and other forms in metal components. For engineers and procurement managers in Milwaukee and across Wisconsin, understanding this process helps in selecting the right vendor and optimizing part design for production.

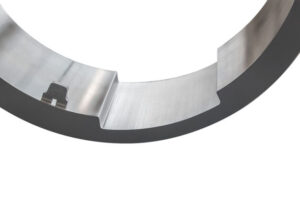

What Is a Keyway and Why It Matters in Power Transmission

A keyway is a slot machined into a shaft or hub to fit a key that locks rotating elements together. This connection ensures torque transfer between the shaft and mating component, maintaining synchronization under load.

Keyways are essential in many industries, including:

- Automotive and transportation

- Aerospace manufacturing

- Industrial machinery

- Renewable energy systems

Precision is critical when machining keyways. Even a slight deviation in alignment or depth can cause imbalance or premature wear in the assembly. That is why keyway broaching services in Milwaukee are trusted by manufacturers who demand accuracy and consistency.

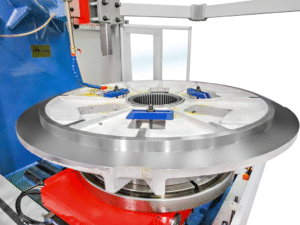

Understanding Splines and How They Differ from Keyways

While keyways use a single key to transmit torque, splines use multiple ridges or teeth that engage with corresponding grooves in the mating component. This multi-tooth design distributes torque more evenly, enhancing mechanical strength and rotational stability.

Types of Splines Commonly Broached

| Type | Description | Typical Applications |

| Involute Splines | Feature curved teeth for uniform load distribution and self-centering. | Automotive shafts, transmission systems |

| Parallel Splines | Have straight-sided teeth for simple alignment. | Industrial couplings, pumps |

| Serration Splines | Contain fine, closely spaced teeth for lightweight assemblies. | Aerospace, robotics |

In manufacturing, spline broaching in Wisconsin enables the creation of complex, repeatable internal profiles that ensure smooth torque transfer and long-term durability.

What Is Contract Broaching?

Contract broaching involves outsourcing the broaching operation to a specialized service provider rather than performing it in-house. For many manufacturers, this approach offers multiple advantages—cost savings, access to expertise, and flexible capacity.

Key Benefits of Contract Broaching

- Reduced Capital Investment

Purchasing and maintaining broaching machines can be costly. Contracting allows you to use advanced equipment without the upfront expense. - Access to Technical Expertise

Experienced broaching providers, such as Broaching Technologies’ Services, have the capability to handle challenging geometries, materials, and tolerances. - Scalability

Contract broaching offers the flexibility to process both short runs and large production volumes without compromising on precision. - Faster Turnaround Times

With dedicated equipment and tooling setups, outsourcing can accelerate production schedules and eliminate downtime.

For Milwaukee-based manufacturers, working with a local contract broaching partner provides logistical advantages such as reduced shipping time and closer technical collaboration.

Blind vs Through Keyway Broaching

There are two primary types of keyway broaching blind and through broaching. Each method serves a specific purpose depending on the component’s geometry and design requirements.

Through Keyway Broaching

Through keyways extend completely through the part. This method allows for straightforward chip evacuation and faster cycle times. It is ideal for components like couplings or pulleys that require continuous slots.

Blind Keyway Broaching

Blind keyways stop at a defined depth within the part. Because the slot does not extend through, this process requires careful chip management and specialized tooling. It is suitable for gears and components that demand closed-end slots.

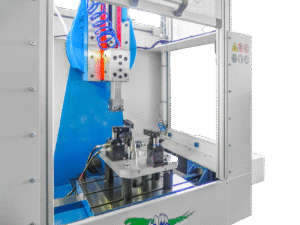

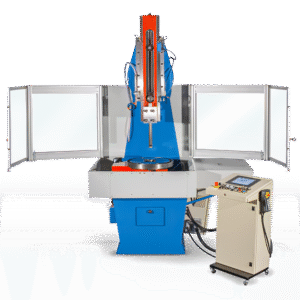

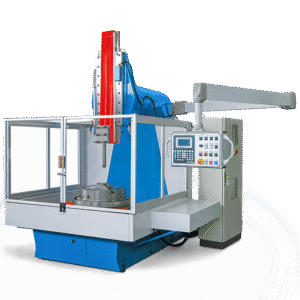

Broaching Technologies uses advanced machines capable of performing both processes with consistent precision, ensuring high-quality finishes even in difficult-to-machine materials.

Materials Used in Broaching

Different materials respond uniquely during the broaching process. Understanding material-specific challenges ensures accuracy and prolongs tool life.

Stainless Steel

Known for strength and corrosion resistance, stainless steel requires sharp tools and controlled cutting parameters to prevent work hardening.

Aluminum

Lightweight and ductile, aluminum broaching demands proper chip evacuation and cooling to maintain surface integrity.

Brass and Copper Alloys

These softer metals allow higher cutting speeds but require fine-tuned tooling to achieve consistent dimensions.

Carbon and Alloy Steels

Used extensively in automotive and machinery components, carbon steels require rigid setups and precise lubrication during broaching.

At Broaching Technologies, our facility is equipped to handle a wide variety of metals, maintaining exact tolerances across all materials

Evaluating a Contract Broaching Vendor

Selecting a broaching service provider involves more than comparing prices. The right partner should demonstrate technical competence, process control, and quality assurance.

Factors to Consider

- Equipment and Tooling Capability

Confirm that the vendor has modern broaching machines capable of handling the size, length, and type of slot your component requires. - Inspection and Quality Control

High-precision industries depend on consistent accuracy. Vendors should have inspection protocols such as CMM verification and surface finish checks. - Experience with Multiple Materials

A reliable provider can work across a range of metals, from stainless steel to high-strength alloys. - Process Transparency

Ask about tool maintenance, broach grinding, and tolerance verification. A transparent process ensures repeatable results. - Lead Times and Flexibility

Reliable turnaround times are essential for maintaining your production schedule.

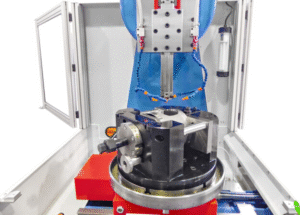

The Broaching Process: From Setup to Delivery

A well-executed contract broaching process involves several precise steps:

- Design Review – Engineers review the component drawing, identify tolerances, and select the appropriate broach.

- Tool Setup and Calibration – Machines are aligned, and feed rates are optimized.

- Broaching Operation – The broach cuts progressively, shaping the internal or external form in one pass.

- Inspection and Verification – Each part undergoes dimensional checks and surface analysis.

- Finishing and Delivery – Cleaned and packaged parts are shipped according to customer specifications.

This controlled workflow ensures accuracy, repeatability, and compliance with engineering standards.

Why Milwaukee Is a Hub for Precision Broaching

Milwaukee’s industrial base makes it a strategic location for advanced machining services. With its concentration of manufacturing and engineering expertise, the region supports a high demand for keyway and spline broaching.

Manufacturers in Wisconsin choose local partners to minimize logistics costs, gain faster service, and maintain close collaboration throughout production. Broaching Technologies’ facility combines local service accessibility with global manufacturing standards, making it a preferred contract broaching provider.

Common Applications of Keyway & Spline Broaching

Keyway and spline broaching are used across a range of industries and components, including:

| Industry | Example Components | Broaching Type |

| Automotive | Transmission shafts, couplings, gears | Keyway and spline broaching |

| Aerospace | Actuator parts, landing gear, pump housings | Blind keyway broaching |

| Industrial Equipment | Hydraulic couplings, rotors, pulleys | Through keyway broaching |

| Energy & Power | Turbine components, motor housings | Internal spline broaching |

These applications highlight the importance of precision and reliability in the broaching process.

Quality Assurance and Process Control

Maintaining quality in contract broaching requires a combination of advanced machinery, skilled technicians, and strict inspection standards. Broaching Technologies follows a structured approach that includes:

- Tooling Maintenance and Grinding: Ensuring sharp, properly shaped tools for consistent performance.

- Surface and Form Inspection: Measuring dimensions and finishes against specification.

- Tolerance Verification: Maintaining precise control within micron-level limits.

Such measures guarantee the functional integrity of each component and its performance in downstream assembly.

Conclusion

Precision in machining defines product quality and reliability. For manufacturers in Milwaukee and Wisconsin, partnering with an experienced contract broaching provider ensures efficiency, accuracy, and consistency across production runs.

Broaching Technologies delivers specialized keyway and spline broaching services, advanced quality assurance, and deep process knowledge that manufacturers can depend on.

For detailed inquiries or project consultations, contact us today to discuss how our team can support your next manufacturing requirement.