Why Spline Type Matters in Mechanical Design

In precision mechanical engineering, choosing the correct spline profile is critical. Splines transmit torque between rotating elements while maintaining alignment and strength. Selecting the right type — involute, parallel, or serrated — can directly affect load capacity, mating reliability, and product life. Improper selection often leads to part failure, increased wear, and unexpected downtime.

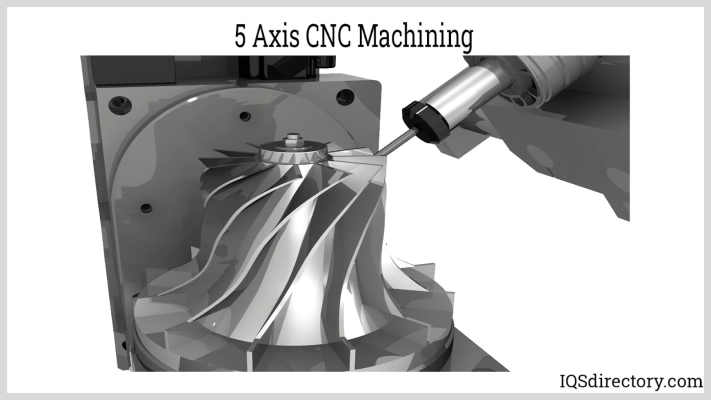

The Role of Broaching in Spline Production

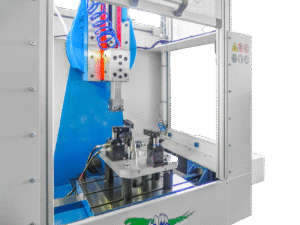

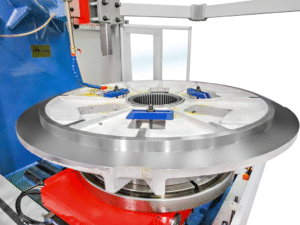

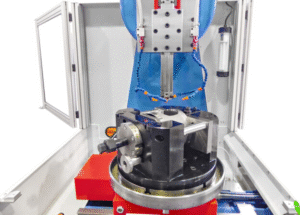

Broaching is one of the most reliable and cost-effective methods for producing internal and external splines. It ensures consistent tooth geometry, accurate tolerances, and high-quality finishes.

Spline broaching is widely used in aerospace, automotive, and heavy machinery sectors where dimensional accuracy and repeatability are paramount.

Overview of Spline Broaching Types

What is Spline Broaching?

Spline broaching involves using a precision-toothed tool to cut internal or external splines in a workpiece. The broach tool progresses linearly through the material, forming each tooth incrementally until the final profile is achieved. This process supports tight tolerances and high repeatability.

Internal vs. External Splines

- Internal Splines: Located inside bores, typically requiring key alignment and torque transfer between concentric parts.

- External Splines: Located on the outer surface of shafts, meshing with corresponding internal components.

Both spline types can use involute, parallel, or serrated geometries, depending on function and design requirements.

Involute Splines Explained

Geometry and Load Distribution

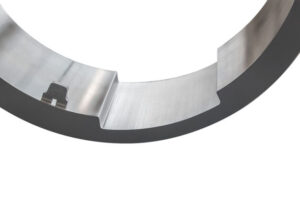

Involute splines feature curved tooth profiles similar to involute gears. Their key advantage lies in consistent pressure angles across mating surfaces, allowing uniform load distribution along the tooth flanks. This reduces stress concentrations, improving fatigue life and strength.

Common Uses and Strength Advantages

- Preferred in high-torque applications such as drive shafts and gear couplings.

- Common in automotive transmissions, aircraft engine systems, and hydraulic pumps.

- Can handle axial and radial loads more efficiently than parallel splines.

- Suited for tight tolerance assemblies due to self-centering properties.

Parallel Splines Explained

Key Characteristics and Machining Ease

Parallel splines (also called straight-sided splines) have flat-topped teeth with straight sides. Their geometry is easier to manufacture and inspect. Parallel splines provide straightforward engagement and are often used when self-centering is not critical.

Applications and Limitations

- Common in agricultural equipment, machine tools, and industrial couplings.

- Less effective for high-torque or misalignment-prone scenarios.

- Not as strong under load as involute splines.

- Better suited for applications where cost efficiency and machining simplicity are priorities.

Serrated Splines Explained

Fine Tooth Design and Fit

Serrated splines feature a high tooth count with a saw-tooth profile, offering enhanced grip in smaller assemblies. This spline type is often used in miniature components or parts where space constraints exist but rotational alignment is still essential.

When to Use Serration Splines

- Electronic connectors, instrumentation systems, and light-duty applications.

- Ideal for press-fit or interference-fit designs.

- Provide good rotational indexing where torque loads are minimal.

- Not suitable for transmitting large amounts of torque or withstanding repetitive high-stress cycles.

Comparing Spline Performance and Fit

Torque Transmission Capabilities

- Involute splines lead in torque transfer, followed by parallel, then serrated.

- Involute profiles distribute load across the tooth length, while parallel splines often concentrate stress at the edges.

Material Compatibility

- Involute splines require hardened materials to resist wear under load.

- Parallel and serrated splines can be used with a broader range of materials, including some non-ferrous metals, depending on torque and fitment needs.

Tolerances and Precision Requirements

- Involute splines offer the tightest tolerance capabilities and are often broached with tolerances as tight as +0.0005″.

- Parallel splines are easier to inspect but allow for more variation.

- Serrated splines require high-precision broaching due to smaller profile sizes.

Application-Based Recommendations

Aerospace vs. Automotive vs. Industrial Equipment

- Aerospace: Involute splines are standard due to high strength-to-weight requirements and tight assembly specifications.

- Automotive: Involute splines dominate in drivetrains and gearboxes; parallel splines may be used in steering or suspension systems.

- Industrial Equipment: Mix of parallel (for rugged, cost-sensitive environments) and involute (for power transmission and rotating couplings).

Cost and Production Efficiency Considerations

- Involute Splines: Highest cost due to tooling complexity and inspection, but best for durability and precision.

- Parallel Splines: More affordable and quicker to produce, especially for high-volume, moderate-tolerance applications.

- Serrated Splines: Low-cost for small, light-load parts; minimal tooling cost but specialized alignment required.

Conclusion

Key Takeaways for Spline Profile Selection

Selecting the correct spline profile is vital for ensuring part performance, durability, and alignment. Involute splines offer superior torque and alignment features. Parallel splines excel in manufacturability and cost-efficiency. Serrated splines are ideal for compact, precision index applications.

Understanding the function and mechanical context of your design ensures spline selection isn’t just a design checkbox, but a key part of engineering performance.

Request a Spline Broaching Design Review

Need help selecting or designing the optimal spline for your component? Contact our engineering team for a spline broaching review. We’ll guide you through profile selection, material compatibility, and broach tooling requirements to ensure flawless production results.

Involute splines have curved teeth for smooth load distribution and high torque transfer. Parallel splines have straight-sided teeth, are easier to manufacture, but typically handle lower torque loads.Involute splines provide better torque transfer due to their load-distributing tooth geometry and self-centering characteristics. Yes. Involute, parallel, and serrated splines can be internally broached. However, tooling and precision requirements vary depending on the profile complexity and material. Common materials include carbon steel, alloy steel, stainless steel, aluminum, and titanium. Material selection depends on application-specific torque, load, and wear requirements. Consider application load, assembly precision, cost constraints, and mating component geometry. Involute splines are best for high torque; parallel for simplicity and cost; serrated for compact, low-load assemblies.