The Growing Demand for Precision Broaching

Modern manufacturing demands consistently precise, high-strength components capable of performing in high-torque and high-stress applications. Keyways, splines, and slots are integral to these assemblies, requiring processes that can achieve tight tolerances and reliable repeatability. As machining technology advances, manufacturers often weigh whether to invest in CNC in-house broaching setups or partner with a dedicated contract broaching service.

The rise in demand for complex parts in aerospace, automotive, defense, and industrial equipment sectors has put added pressure on production planners to optimize workflows while ensuring quality and compliance. Broaching operations, once an afterthought, are now strategic decisions affecting throughput, product reliability, and overall manufacturing economics.

Broaching Options: Outsourcing vs. In-house CNC

The decision isn’t always straightforward. Both contract broaching services and CNC in-house broaching offer unique advantages depending on production volume, budget, tolerances, and complexity. This guide compares both options so engineering managers and production leads can make informed, cost-effective decisions tailored to their application requirements and production strategy.

What is Contract Broaching?

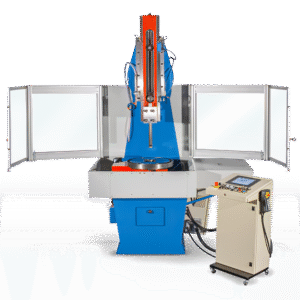

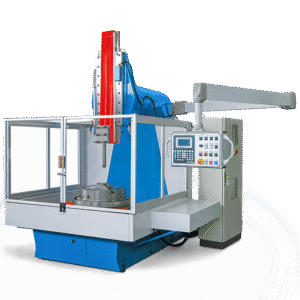

Process Overview

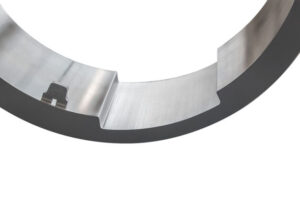

Contract broaching involves outsourcing your broaching operations to a specialized machine shop equipped with advanced broaching machines and custom tooling. These facilities handle blind and through keyways, internal splines, precision slots, and serrations for various industries. Their services often include engineering consultation, tooling design, inspection reporting, and expedited delivery options.

Benefits and Typical Applications

Key benefits include:

- Access to advanced equipment without capital investment

- Custom tooling for complex or high-precision jobs

- Scalable high-volume production or prototype flexibility

- Certified quality control and documented inspection reports

- Reduced operational overhead and maintenance expenses

Typical applications include aerospace couplings, automotive shafts, industrial pump housings, defense mechanisms, and power transmission components requiring exact tolerances and repeatability.

What is CNC In-house Broaching?

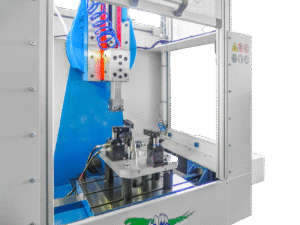

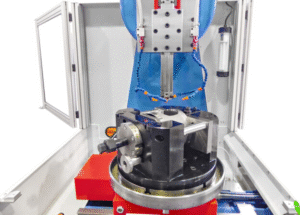

How CNC Broach Tools Work

CNC broaching tools allow manufacturers to machine internal and external profiles using existing CNC lathes or mills. Special broach tools and holders are programmed into the CNC machine tool path, cutting precision keyways and splines without dedicated broaching equipment. This method is increasingly popular for prototype development and smaller production runs.

Benefits and Limitations

Benefits:

- Faster prototype development and single-piece runs

- Eliminates shipping parts to third parties

- Integrates into existing CNC workflows

- Reduces outsourcing lead times for small batches

Limitations:

- Limited to simpler profiles and moderate tolerances

- Increased tool wear without dedicated setups

- Not cost-effective for high-volume production

- Often lacks dedicated quality inspection capabilities for broaching tolerances

Key Comparison Factors

Cost-Per-Part Analysis

Contract Broaching: More economical for medium-to-large volume runs as tool amortization is spread across parts. No need for capital equipment or additional staffing. Competitive per-part pricing is achieved due to dedicated machine uptime and experienced operators.

CNC In-house: Ideal for small batches and prototypes. Higher cost per part as tooling life is limited, and broaching cycle times are longer on CNC machines. Each broach tool setup also adds to operational downtime, especially for small series jobs.

Lead Time and Flexibility

Contract Broaching: Faster for high-volume orders and complex profiles due to optimized setups, machine availability, and dedicated tooling inventories.

CNC In-house: Best for urgent, one-off parts or R&D prototypes, where immediate in-house control is critical. However, managing tool changes and programming adjustments for broaching adds complexity to shop floor scheduling.

Tolerances and Quality Assurance

Contract Broaching: Achieves tight tolerances, often within ±0.0005”. Equipped with coordinate measuring machines (CMMs), SPC software, and in-process inspection protocols for documentation and traceability.

CNC In-house: Typically holds broader tolerances, acceptable for non-critical applications or adjustable fits. In high-precision applications, tolerance drift due to tool deflection and wear is more likely without specialized broaching machines.

Tooling Costs and Maintenance

Contract Broaching: Tooling costs are absorbed by the contract shop. No maintenance, replacement, or sharpening responsibilities for the client. This simplifies procurement, budgeting, and scheduling.

CNC In-house: Requires ongoing investment in broach tools, holders, inserts, and gauge blocks, plus potential downtime for tool changes and wear adjustments. Sharpening broaches internally demands skilled personnel and dedicated grinding setups.

Production Volume Considerations

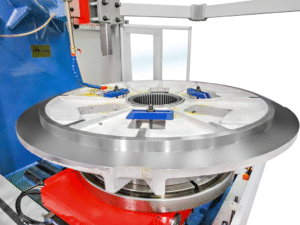

Contract Broaching: Scales efficiently for hundreds to thousands of parts per order. Larger orders benefit from economies of scale, optimized setups, and part pricing discounts.

CNC In-house: Practical for quantities under 50 pieces, beyond which dedicated broaching becomes faster and more economical. Limited machine availability and longer cycle times can lead to scheduling conflicts in larger production runs.

When Should You Choose Contract Broaching?

Complex Profiles or Tight Tolerances

When parts demand intricate internal splines, blind keyways, or tolerances tighter than ±0.001”, contract broaching ensures the precision, inspection resources, and repeatability required for mission-critical parts.

High-Volume Runs or Limited In-house Capacity

Contract services alleviate production bottlenecks, especially during peak demand periods or when high volumes would strain in-house resources. Dedicated broaching shops offer quick setup changes, reducing lead times.

ISO-Certified Quality Requirements

If your industry or clients require ISO, AS9100, or ITAR certification, contract broachers often hold these credentials, providing traceability and inspection documentation. Their inspection departments often integrate CMM reports and SPC analysis.

When is CNC In-house Broaching Better?

Low-Volume or Prototype Work

For one-off components, prototypes, or small production runs, in-house CNC broaching minimizes lead time and eliminates transportation and logistics costs. It’s particularly useful when part design revisions are frequent.

Quick Turnaround Projects

When a part is urgently needed for testing, repair, or customer approval, using an in-house CNC setup ensures same-day delivery without lead time penalties. This agility can prevent costly production delays.

Existing CNC Capabilities in the Shop

If your shop already has CNC turning or milling centers with spare capacity, adding a broach tool holder can extend your service offerings without substantial investment. This improves vertical integration and production control.

Real-World Case Examples

Automotive Supplier: Cost-Per-Part Savings

A Tier 2 automotive supplier outsourced broaching for a 500-piece gearbox shaft order. By using a contract broaching service, the supplier saved 30% on cost per part, eliminated tool maintenance expenses, and met a demanding three-week delivery schedule. The broached keyways held ±0.0005” tolerances consistently across the entire batch.

Aerospace Contractor: Tight Tolerance Achievement

An aerospace contractor required internal splines with ±0.0005” tolerance for a flight-critical component. In-house CNC broaching couldn’t hold the tolerance due to tool deflection in titanium. A contract broaching partner achieved consistent, certified results with documented CMM reports and SPC data, allowing the contractor to secure FAA approval.

Conclusion

Decision Factors Recap

The choice between contract broaching and CNC in-house broaching depends on production volume, required tolerances, lead time, and available equipment. High-volume, tight-tolerance, or complex jobs favor contract services, while prototypes and small runs benefit from CNC broaching flexibility.

For manufacturers seeking ISO-certified results, inspection traceability, and economies of scale, contract broaching is often the superior long-term solution. Meanwhile, in-house CNC broaching offers unmatched agility for prototype development and short-run production.

Get a Broaching Consultation

If you’re weighing broaching options for your next project, contact our engineering team. We’ll assess your specifications, production goals, and tolerance requirements to recommend the most cost-effective, precision-focused solution for your application.