Contract broaching services

offer specialized, high-precision machining processes where manufacturers outsource broaching operations to experts with advanced tooling, calibrated machinery, and rigorous quality control systems. This ensures tight tolerances, efficient production rates, and consistent results across high and low-volume runs.

What is Broaching in Manufacturing?

The Broaching Process Explained

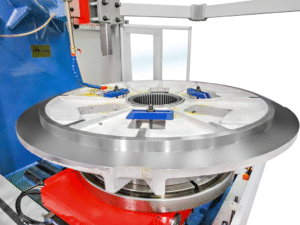

Broaching is a machining process that uses a toothed tool — called a broach — to remove material in a consistent, linear motion. It’s ideal for creating precision internal and external profiles such as keyways, splines, and slots. Broaching provides high-quality finishes and tight tolerances with minimal secondary operations.

Key Industries and Applications for Broaching

Industries like aerospace, automotive, defense, and industrial equipment manufacturing rely on broaching for components requiring exact dimensions, smooth finishes, and structural integrity. Applications include producing keyways in gears, shafts, bushings, couplings, and power transmission components.

What is the Difference Between Blind and Through Keyways?

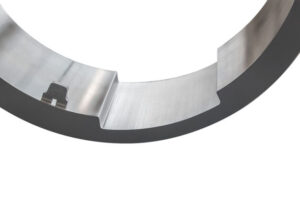

Defining a Blind Keyway

A blind keyway is a machined slot that stops short of penetrating through the entire length of the workpiece. It has a defined start and stop point within the part. This design is crucial when open ends might weaken the component, affect alignment, or compromise sealing.

Defining a Through Keyway

A through keyway is cut completely through the entire length or depth of the component, typically from one end to the other. It allows a key to pass through or sit flush along the entire length of the shaft or bore.

Visual and Functional Differences

The primary distinction lies in whether the keyway extends entirely through the part. Blind keyways provide enhanced structural integrity and improved aesthetics, while through keyways offer straightforward manufacturing and assembly advantages, especially in high-torque applications.

Key Factors Influencing Precision in Broaching

Broaching Tolerances and Dimensional Accuracy

Precise broaching tolerances — often within +0.0005” to -0.0000” — are vital to ensure correct fit, load distribution, and operational reliability. Tight tolerances reduce play and wear in mechanical assemblies, preventing failures in demanding environments.

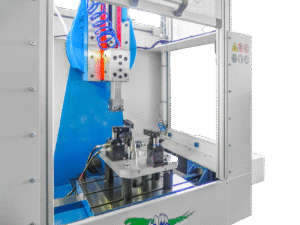

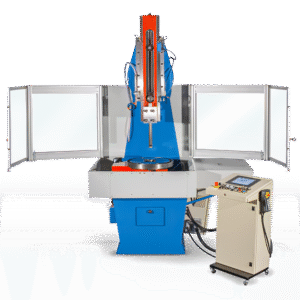

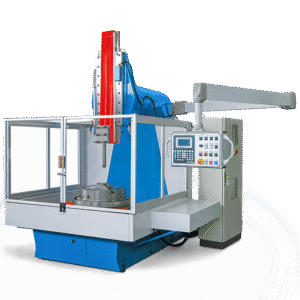

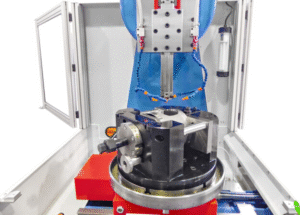

Machine Calibration and Tooling Consistency

Contract broaching shops use meticulously calibrated, CNC-controlled broaching machines that ensure repeatability and exacting precision. Additionally, custom broach tooling is designed and maintained for each specific job, ensuring consistent tooth wear and accurate profiles.

Material Type and Workpiece Hardness

Different materials — from mild steel to high-strength alloys — require adjusted feed rates, tool geometries, and machine settings. A thorough understanding of material behavior under broaching forces is key to achieving optimal results.

Contract Broaching vs. In-house Broaching: When to Choose What

Cost-Per-Part and Lead Time Considerations

Contract broaching typically reduces capital equipment investments and tool maintenance costs for manufacturers. It also improves lead times, especially for complex profiles or high-volume orders, as contract shops maintain large broach inventories and dedicated setups.

Quality Control and Inspection Capabilities

Outsourced broaching providers offer certified inspection systems, CMM verification, and statistical process control to guarantee dimensional accuracy and repeatability — capabilities often too costly for smaller in-house setups.

Material and Application Considerations for Keyway Broaching

Common Materials: Steel, Stainless, Aluminum, Alloys

Keyways are frequently broached into materials like carbon steel, stainless steel, aluminum, and specialty alloys. Each material requires specific tooling and broaching parameters to maintain surface finish and dimensional integrity.

Application Examples: Aerospace, Automotive, Power Transmission

In aerospace, precision keyways are critical for rotors, engine mounts, and couplings. In automotive manufacturing, they’re essential for drive shafts and gearbox components. Power transmission assemblies rely on keyways for secure, vibration-free connections in rotating equipment.

Our Approach to Precision in Blind and Through Keyways

Custom Tooling and Broach Selection

We design and manufacture custom broaches for each application, whether for blind or through keyways. This ensures optimized tooth profiles, feed rates, and finish requirements tailored to the workpiece material and geometry.

Quality Standards and Inspection Protocols

Our ISO-certified processes incorporate in-process inspections, CMM checks, and documented quality protocols. Every keyway we produce adheres to strict dimensional and surface finish criteria, verified against client specifications.

Achieving Tight Tolerances for Critical Components

By combining advanced CAM programming, CNC broaching technology, and skilled technicians, we routinely achieve tolerances as close as +0.0005”. Our ability to control critical dimensions ensures product reliability, particularly in safety-critical applications.

Why Choose Our Contract Broaching Services

ISO-Certified Processes

Our facility adheres to ISO quality standards, ensuring every job follows documented procedures, rigorous inspections, and traceable data records.

Experienced Engineering Team

Our team of seasoned manufacturing engineers provides expert guidance on broaching feasibility, design modifications, and tolerance recommendations to optimize product performance.

High-Volume and Prototype Capabilities

Whether you require a single prototype or thousands of production parts, our flexible broaching capacity, fast tooling setups, and scalable operations ensure timely delivery without sacrificing quality.

Conclusion

Summary of Key Takeaways

Understanding the differences between blind and through keyways, and the factors influencing

broaching precision, is crucial for reliable mechanical assembly performance. Contract broaching services provide an efficient, quality-focused solution for manufacturers requiring high-tolerance, application-specific keyways.

How to Request a Quote or Consultation

Contact our engineering team today to discuss your keyway broaching requirements, request a quote, or arrange a prototype evaluation. Experience the accuracy and consistency of our contract broaching services firsthand.

A keyway is a machined groove or slot in a shaft or mating component that holds a key, securing the parts together in rotational applications. Blind keyways are used when strength, aesthetics, or sealing are priorities, while through keyways simplify manufacturing and are ideal for high-torque or adjustable applications. Common materials include carbon steels, stainless steels, aluminum, brass, titanium, and specialty alloys, each requiring unique tooling and parameters. Tight broaching tolerances ensure proper fit, minimize wear, and maintain mechanical integrity in assemblies subjected to stress and vibration. Outsourcing is ideal when high precision, complex profiles, large quantities, or cost savings on capital equipment and tooling are priorities..